Steel Insulated Roof Panels A Comprehensive Guide

Steel insulated roof panels are revolutionizing the roofing industry, offering a blend of durability, energy efficiency, and aesthetic appeal. These panels, constructed with a steel exterior and an insulating core (often polyurethane or polyisocyanurate), provide superior protection against the elements while significantly reducing energy costs. This guide dives deep into the world of steel insulated roof panels, exploring their various types, applications, installation, and long-term benefits. We’ll cover everything from choosing the right panel for your specific needs to understanding the environmental impact and cost-effectiveness of this increasingly popular roofing solution.

From commercial buildings to agricultural structures, steel insulated roof panels are proving their versatility and resilience. We’ll explore the different core materials, manufacturing processes, and lifespan expectations to help you make informed decisions. We’ll also delve into design considerations, installation techniques, and the crucial role of proper insulation and ventilation in maximizing the benefits of this roofing system.

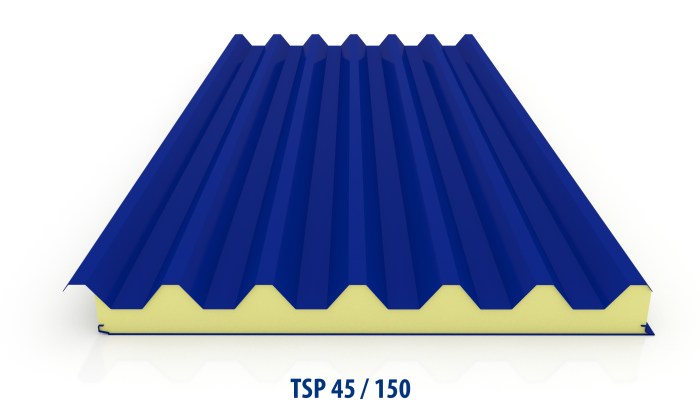

Types of Steel Insulated Roof Panels

Source: nucorbuildingsystems.com

Steel insulated roof panels are a popular choice for commercial and industrial buildings due to their strength, durability, and energy efficiency. They come in a variety of types, each with its strengths and weaknesses depending on the specific application and climate. Understanding these differences is crucial for making an informed decision.

Core Material Types and Steel Gauge Variations

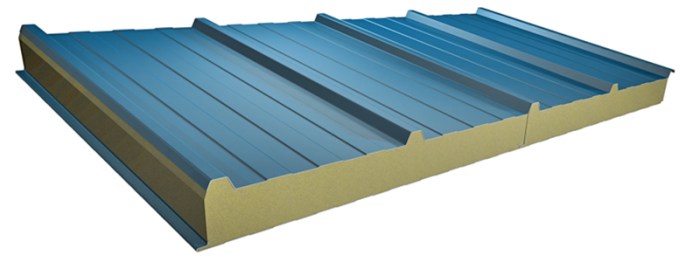

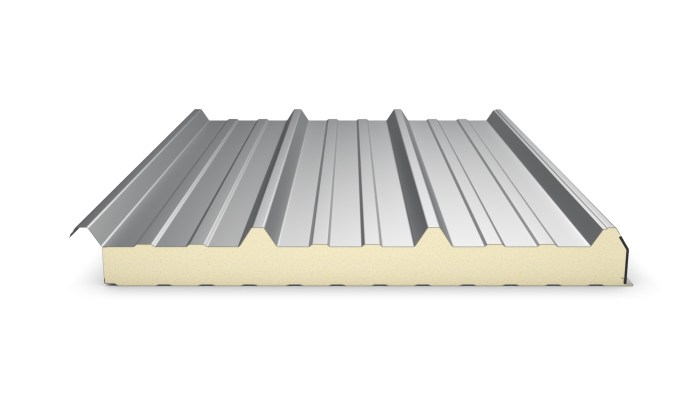

The core material and steel gauge significantly impact the performance of a steel-insulated roof panel. Common core materials include polyurethane (PU), polyisocyanurate (PIR), and mineral wool. Steel gauges, measured in thickness (e.g., 26 gauge, 24 gauge), affect the panel’s strength and weight. Thicker gauges are stronger but heavier and more expensive.

| Panel Type | Core Material | Steel Gauge (Example) | Thermal Performance (R-value) | Cost | Durability |

|---|---|---|---|---|---|

| Standard PU Panel | Polyurethane | 26 gauge | R-20 to R-30 | Medium | Good |

| High-Performance PIR Panel | Polyisocyanurate | 24 gauge | R-30 to R-40+ | High | Excellent |

| Mineral Wool Panel | Mineral Wool | 24 gauge | R-20 to R-30 | High | Good |

Note: R-values are approximate and vary based on thickness and specific manufacturer. Cost and durability are relative comparisons.

Manufacturing Processes

The manufacturing process generally involves several key steps, regardless of the core material used. First, the steel sheets are formed into the desired profile (e.g., corrugated, ribbed). Then, the core material is applied as a continuous layer between the steel sheets. This is often done using a continuous foaming process for polyurethane and polyisocyanurate. For mineral wool, the process may involve inserting pre-formed slabs of insulation. Finally, the entire assembly is cured and the edges are sealed to create a watertight and thermally efficient panel. Variations in the precise techniques and equipment used can account for differences in final product quality.

Lifespan and Maintenance

The lifespan of steel insulated roof panels depends heavily on the quality of materials, the installation process, and the environmental conditions. With proper installation and maintenance, high-quality panels with PIR cores can last 30 years or more. Panels with PU cores generally have a slightly shorter lifespan, typically 20-25 years. Mineral wool panels offer good durability but may be more susceptible to moisture damage if not properly installed. Regular inspections for signs of damage, such as rust, dents, or leaks, are essential for maintaining the longevity of the panels. Minor repairs, like replacing damaged sections, are usually feasible, extending the overall life of the roofing system. In harsh environments, more frequent inspections may be necessary.

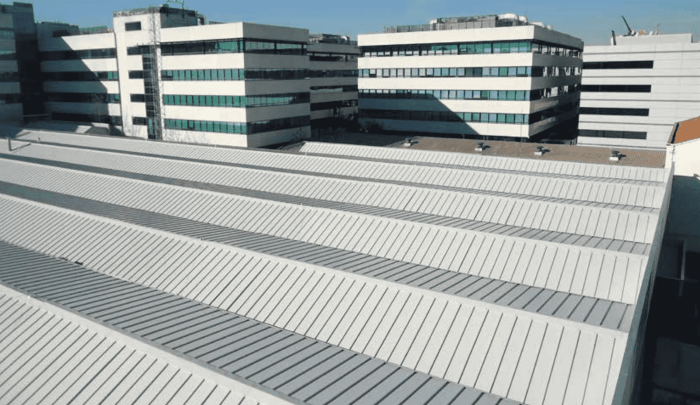

Applications of Steel Insulated Roof Panels

Source: imimg.com

Steel insulated roof panels offer a versatile and durable solution for roofing various structures, providing excellent insulation and weather protection. Their application spans numerous industries, influenced by factors like climate, building design, and specific functional requirements. The following sections detail these applications and explore how panel selection can optimize performance.

Applications Across Industries

The robust nature and customizable features of steel-insulated roof panels make them suitable for a wide range of projects. Their strength, longevity, and energy efficiency contribute to their popularity in various sectors.

- Commercial Buildings: Retail spaces, office complexes, and shopping malls frequently utilize these panels for their aesthetic appeal and ability to create large, uninterrupted roof spans. The panels’ clean lines and various color options allow for seamless integration into modern architectural designs. For example, a large retail store might use panels with a high R-value to minimize energy consumption for heating and cooling.

- Industrial Facilities: Warehouses, factories, and manufacturing plants benefit from the strength and durability of steel insulated panels. The panels can withstand heavy loads and harsh environmental conditions, ensuring long-term protection for valuable equipment and inventory. Consider a large distribution center, where the panels’ resistance to impact and corrosion is crucial for protecting goods and maintaining a stable interior environment.

- Agricultural Structures: From barns and stables to greenhouses and poultry houses, steel insulated roof panels provide excellent insulation and protection against the elements. The panels’ ability to maintain a consistent internal temperature is particularly beneficial for livestock and sensitive crops. Imagine a modern agricultural facility using panels with enhanced thermal performance to minimize energy costs associated with climate control for livestock housing.

Panel Suitability for Different Climates, Steel insulated roof panels

Choosing the right panel type is crucial for optimal performance in various climates. Factors like insulation thickness, core material, and coatings significantly impact the panel’s ability to withstand extreme temperatures and weather conditions.

- Cold Climates: In regions with harsh winters, panels with high R-values and enhanced insulation are essential to minimize heat loss. Polyurethane or polyisocyanurate core materials are typically preferred for their superior thermal performance. A northern warehouse, for instance, might use panels with a higher R-value to reduce heating costs and maintain a consistent internal temperature.

- Hot Climates: In hot and sunny regions, panels with reflective coatings can help reduce solar heat gain and maintain a cooler interior environment. These coatings can significantly reduce the building’s cooling load, leading to energy savings. Think of a large-scale solar farm in the desert southwest using panels with high reflectivity to minimize heat absorption.

- Coastal Regions: In coastal areas prone to high humidity and salt spray, panels with corrosion-resistant coatings are essential for ensuring longevity. Galvanized steel or other corrosion-resistant materials are often used to protect the panels from deterioration. A seaside restaurant might choose panels with a special coating to withstand the harsh coastal environment.

Innovative Architectural Designs

Steel insulated roof panels are no longer just functional components; they’re integral elements in creating visually striking and innovative architectural designs. Their versatility allows for creative applications that push the boundaries of traditional roofing systems.

- Curved Roofs: The panels’ flexibility allows for the creation of curved and arched roofs, adding a unique aesthetic element to buildings. The smooth, continuous surface of the panels contributes to a modern and sleek appearance. Imagine a contemporary museum featuring a dramatic curved roof constructed using steel insulated panels.

- Green Roofs: Steel insulated panels can be integrated into green roof systems, providing a sustainable and environmentally friendly roofing solution. The panels’ strength and durability support the weight of the vegetation and soil, while their insulation properties help regulate the temperature of the roof. Consider a sustainable office building incorporating a green roof with steel insulated panels underneath to improve energy efficiency and aesthetics.

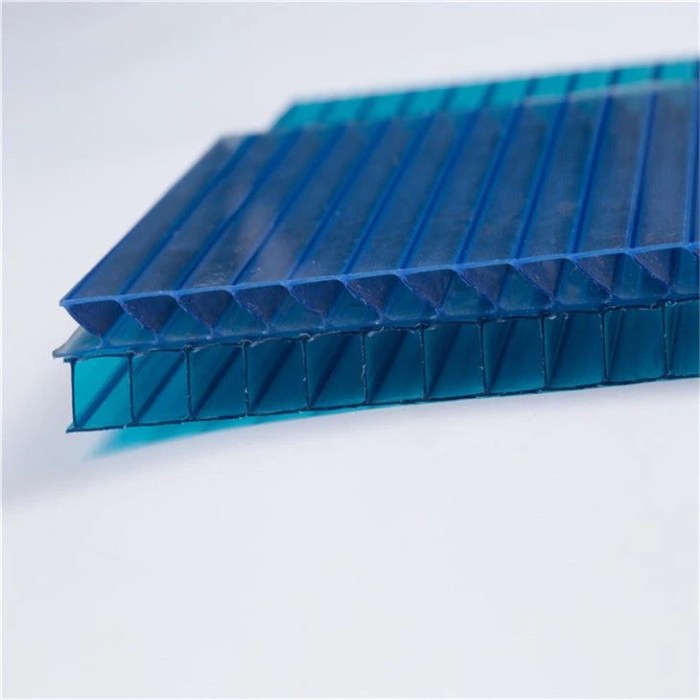

- Skylights and Translucent Panels: The incorporation of skylights and translucent panels can introduce natural light into buildings, reducing the need for artificial lighting and creating a more pleasant interior environment. These features can be seamlessly integrated into the overall roof design, enhancing both functionality and aesthetics. Visualize a modern factory building with strategically placed translucent panels to maximize natural daylighting and reduce energy costs.

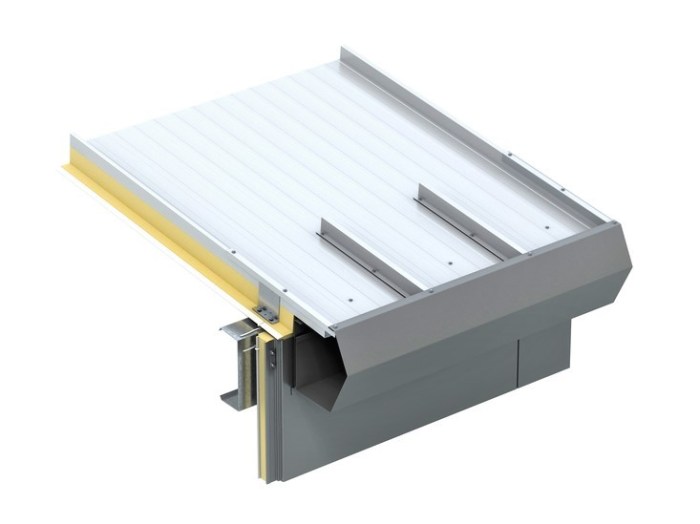

Installation and Design Considerations

Source: topwaysteel.com

Installing steel insulated roof panels requires careful planning and execution to ensure a long-lasting, energy-efficient, and structurally sound roof. Proper installation techniques, along with understanding the importance of insulation and ventilation, are crucial for optimal performance. This section details the process and key considerations for successful roof panel installation.

Step-by-Step Installation Process

A well-organized installation process minimizes errors and ensures a quality result. The following steps provide a general guideline; always refer to the manufacturer’s specific instructions for your chosen panels. Safety is paramount throughout the entire process.

- Preparation: Begin by ensuring the roof deck is clean, level, and structurally sound. Address any existing damage or imperfections. Check for proper slope and drainage. Gather all necessary tools and materials, including safety equipment.

- Panel Handling and Storage: Handle panels carefully to avoid damage. Store them flat on a stable surface, protected from the elements. Follow manufacturer’s recommendations for handling and storage.

- Fastening: Start installation at the lowest point of the roof, typically at the eave. Secure the first panel using appropriate fasteners, ensuring proper spacing and alignment. Use a self-tapping screw or a combination of screws and clips depending on the design.

- Panel Interlocking: Interlock subsequent panels according to the manufacturer’s instructions. Ensure a tight, weather-resistant seal at each joint. Use caulking where needed to prevent leaks.

- Flashing and Sealing: Install flashing around penetrations such as vents, chimneys, and skylights to prevent water ingress. Seal all joints and seams with appropriate sealant to maintain a waterproof barrier.

- End Caps and Trim: Install end caps and trim pieces to complete the installation and provide a professional finish. Ensure proper alignment and secure fastening.

- Inspection: Thoroughly inspect the completed installation for any gaps, leaks, or damage. Address any issues immediately.

Insulation and Ventilation

Proper insulation and ventilation are critical for energy efficiency and longevity of the roof system. Inadequate insulation can lead to increased energy costs and potential condensation problems, while insufficient ventilation can trap moisture, leading to mold growth and structural damage. The type and thickness of insulation should be selected based on climate and building code requirements. Ventilation systems should be designed to ensure adequate airflow to remove moisture and prevent heat buildup.

Structural Considerations for Different Roof Designs and Panel Types

The structural design of the roof must be able to support the weight of the steel insulated panels and any additional loads, such as snow or wind. Different panel types have varying weight and strength characteristics, requiring appropriate design considerations. The choice of fastening method also influences the structural integrity of the roof system.

| Fastening Method | Suitable Panel Types | Applications | Advantages |

|---|---|---|---|

| Self-tapping screws | Most panel types | General roofing applications | Cost-effective, relatively easy to install |

| Standing seam clips | Standing seam panels | High-performance roofing systems | Excellent weather tightness allows for thermal expansion |

| Hidden fastener systems | Specific panel designs | Aesthetically pleasing roofs | Clean, seamless appearance |

| Combination systems (screws and clips) | Various panel types | Complex roof designs | Versatile, adaptable to different conditions |

Environmental Impact and Sustainability

Source: fse-ok.com

Steel insulated roof panels, while offering numerous advantages in terms of durability and energy efficiency, have an environmental footprint that needs careful consideration. This section examines the lifecycle impacts of these panels, from material sourcing to disposal, and compares them to alternatives, highlighting their sustainability features.

The manufacturing process of steel insulated roof panels involves several stages with associated environmental impacts. Steel production, a significant component, is energy-intensive, relying heavily on fossil fuels and generating greenhouse gas emissions. The creation of the insulating core, often polyurethane or polyisocyanurate, also consumes energy and uses chemicals with potential environmental consequences. Transportation of materials and finished panels adds to the carbon footprint. Disposal at the end of the panel’s life, if not properly managed, can contribute to landfill waste and potential pollution.

Steel Production and Energy Consumption

Steel production, a major contributor to the environmental impact of steel insulated roof panels, is a process that demands significant energy input. The blast furnace process, a common method, utilizes large amounts of coal and coke, releasing substantial carbon dioxide into the atmosphere. The subsequent rolling and forming of the steel sheets also require energy. However, advancements in steel manufacturing are leading to increased use of recycled steel and more efficient production methods, mitigating some of these impacts. For example, electric arc furnaces, which use scrap steel as their primary feedstock, have a considerably lower carbon footprint than traditional blast furnaces. The overall energy consumption can vary significantly depending on the specific manufacturing processes and the source of energy used.

Comparison with Alternative Roofing Materials

Compared to traditional roofing materials like asphalt shingles or clay tiles, steel insulated roof panels often demonstrate superior long-term environmental benefits. Asphalt shingles have a shorter lifespan, requiring more frequent replacements and contributing to greater landfill waste over time. The extraction and processing of clay for tiles are also energy-intensive. Steel insulated panels, due to their longer lifespan and potential for recyclability, often result in a lower overall environmental impact over their entire life cycle. A life cycle assessment (LCA) comparing various roofing materials would provide a more precise quantitative comparison, considering factors like embodied carbon, energy consumption, and waste generation. Studies have shown that in many instances, steel panels perform favorably in these LCAs.

Recyclability and Sustainable Aspects

Steel is a highly recyclable material. At the end of their service life, steel insulated roof panels can be dismantled, and the steel components can be recycled into new steel products, significantly reducing the need for virgin materials. The core insulation, while less readily recyclable, can in some cases be used for energy recovery. Manufacturers are increasingly incorporating recycled content into their products, further reducing the environmental impact. The use of recycled steel and responsible disposal practices is are key element in achieving a more sustainable lifecycle for steel-insulated roof panels. Several organizations provide certifications and standards related to the sustainability of building materials, which can help consumers identify environmentally responsible products.

Cost Analysis and Economic Benefits

Source: tsscgroup.com

Steel insulated roof panels, while representing a significant upfront investment, offer compelling long-term economic advantages. Understanding the various cost components and their impact on overall return on investment is crucial for informed decision-making. This section will break down the costs and highlight the substantial savings realized through energy efficiency.

The initial cost of a steel insulated roof system is influenced by several factors, including panel type, size, and complexity of the installation. Ongoing maintenance costs are relatively low compared to other roofing materials, leading to significant cost savings over the lifespan of the roof.

Cost Breakdown of Steel Insulated Roof Panels

The total cost of ownership involves several key components. The following table provides a simplified breakdown, acknowledging that actual costs can vary significantly based on project specifics and location.

| Cost Component | Percentage of Total Cost (Estimate) | Factors Influencing Cost | Example Cost (USD per sq ft – approximate) |

|---|---|---|---|

| Material Costs (Panels, Fasteners, Flashing) | 40-50% | Panel type, thickness, insulation type, quantity | $5 – $15 |

| Installation Labor | 30-40% | Project complexity, labor rates, and access to the roof | $3 – $8 |

| Transportation and Delivery | 5-10% | Distance from supplier, project location, quantity | $1 – $3 |

| Permits and Inspections | 5-10% | Local regulations, project scope | $0.50 – $2 |

| Contingency (Unexpected Costs) | 5-10% | Weather delays, material shortages, design changes | $0.50 – $2 |

Note: These are approximate figures and should be considered as a general guide only. Actual costs will vary based on several factors. Consult with roofing professionals for accurate project-specific cost estimates.

Long-Term Cost Savings Through Energy Efficiency

The superior insulation properties of steel-insulated roof panels significantly reduce energy consumption for heating and cooling. This translates into substantial long-term cost savings on utility bills. For example, a building with a poorly insulated roof might spend $10,000 annually on heating and cooling. By upgrading to steel insulated panels, this could be reduced by 30-50%, resulting in annual savings of $3,000-$5,000. These savings accumulate over the lifespan of the roof, quickly offsetting the initial investment.

Total Cost of Ownership Comparison

Comparing the total cost of ownership (TCO) over 20 years reveals the economic advantages of steel-insulated panels. While the initial investment might be higher than that of traditional roofing materials like asphalt shingles, the long-term savings on energy costs, maintenance, and potential roof replacements often make steel insulated panels the more cost-effective option. For instance, a hypothetical comparison might show asphalt shingles requiring a full replacement after 15 years, adding a significant cost to the equation, while steel insulated panels require minimal maintenance and last for 20+ years.

Technical Specifications and Standards

Source: roof-experts.ca

Choosing the right steel insulated roof panel requires understanding the relevant industry standards and technical specifications. This ensures the panels meet building codes, provide adequate performance, and offer long-term durability. Factors like panel dimensions, thickness, load-bearing capacity, fire resistance, and weather resistance are crucial considerations.

Relevant Industry Standards and Building Codes

Steel insulated roof panels must comply with various international and national building codes and industry standards. These standards address aspects such as structural integrity, fire safety, thermal performance, and wind resistance. Specific standards vary by region, so consulting local building codes is essential. Examples include, but are not limited to, those published by organizations like ASTM International (American Society for Testing and Materials) and ISO (International Organization for Standardization). These standards often cover material properties, testing procedures, and performance requirements for metal building materials, including insulated panels. Compliance with these standards is vital for ensuring the safety and longevity of the roof system.

Typical Panel Dimensions, Thicknesses, and Load-Bearing Capacities

The dimensions, thicknesses, and load-bearing capacities of steel insulated roof panels vary significantly depending on the manufacturer and the specific application. Understanding these parameters is crucial for proper design and installation. The following table provides a general overview of typical ranges; however, always refer to the manufacturer’s specifications for exact values.

| Parameter | Typical Range | Units | Notes |

|---|---|---|---|

| Panel Width | 36″ – 48″ | inches | May vary slightly depending on panel profile. |

| Panel Length | Variable, up to 40ft | feet | Custom lengths are often available. |

| Panel Thickness | 2″ – 6″ | inches | Includes the thickness of the steel skins and insulation core. |

| Load-Bearing Capacity | Varies greatly depending on panel thickness, profile, and support structure. | psf (pounds per square foot) | Consult manufacturer’s specifications and structural engineering calculations. |

Fire Resistance and Weather Resistance Properties

Steel insulated roof panels offer inherent fire resistance due to the steel skins and the fire-retardant properties of the insulation core. The specific fire rating depends on the type of insulation used (e.g., polyisocyanurate, polyurethane) and the panel’s construction. Fire resistance ratings are often expressed as a time rating (e.g., 1-hour, 2-hour fire rating) indicating how long the panel can withstand a fire before structural failure. Weather resistance is another crucial aspect. The steel skins are typically coated with a protective layer (e.g., Galvalume, Kynar) to prevent corrosion and provide long-term durability against various weather conditions, including rain, snow, and UV radiation. Proper sealing and installation are also vital for ensuring weather tightness. The insulation core contributes to weather resistance by providing thermal insulation, preventing condensation, and reducing heat transfer.

Last Word

Source: alliedinsulatedpanels.com

Ultimately, steel insulated roof panels represent a smart investment for building owners seeking a durable, energy-efficient, and aesthetically pleasing roofing solution. Their versatility across various applications, coupled with long-term cost savings and reduced environmental impact, makes them a compelling choice for modern construction projects. By understanding the different panel types, installation processes, and design considerations, you can leverage the numerous benefits these panels offer to create a robust and sustainable building envelope. This guide provides a solid foundation for making informed decisions, ensuring your roofing project meets your specific needs and budget.