Insulated Metal Roofing Panels A Comprehensive Guide

Insulated metal roofing panels offer a durable, energy-efficient, and aesthetically pleasing solution for your home or business. These panels combine a strong metal exterior with a core of insulating material, creating a roofing system that provides superior protection from the elements while significantly reducing energy costs. We’ll explore the various types, installation processes, cost considerations, maintenance needs, and environmental impact of this increasingly popular roofing option.

This guide will walk you through everything you need to know, from understanding the different types of insulated metal roofing panels available to properly maintaining your new roof for years to come. We’ll cover the advantages and disadvantages, helping you make an informed decision that best suits your needs and budget.

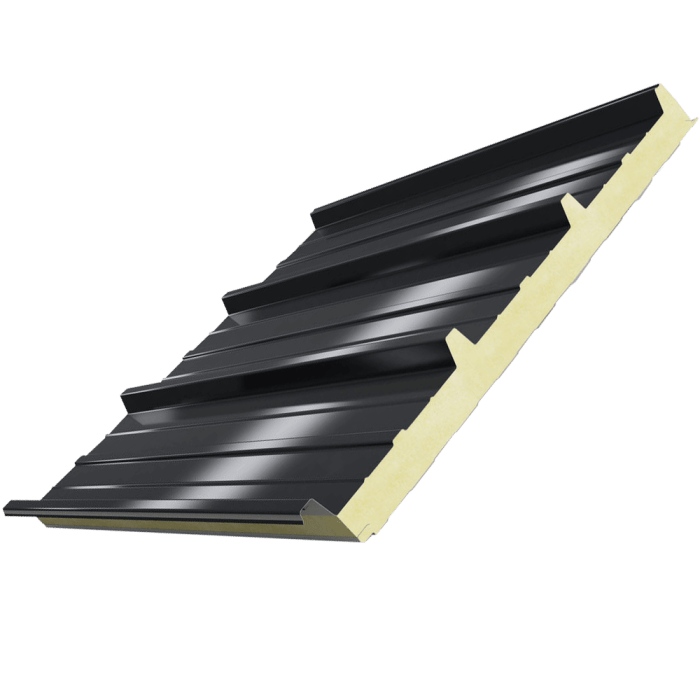

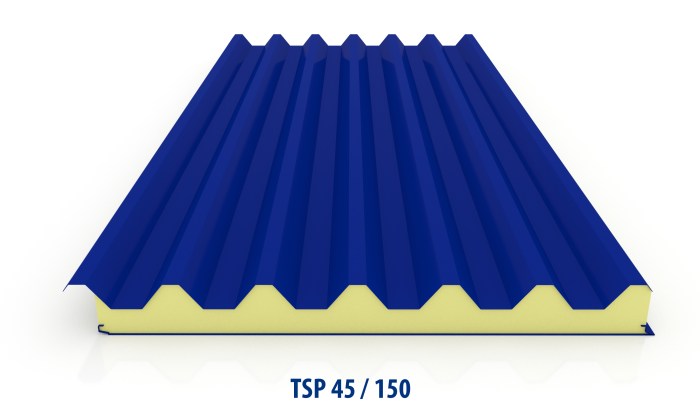

Types of Insulated Metal Roofing Panels

Source: strukturoc.com

Insulated metal roofing panels offer a durable and energy-efficient solution for various building types. Understanding the different types available, their core components, and performance characteristics is crucial for making informed decisions during the selection process. This section details the key features of several common panel types, allowing for a comparison based on your specific needs and climate.

Insulated Metal Roofing Panel Types and Their Core Components

Insulated metal roofing panels consist of a metal facing bonded to an insulating core. The choice of materials for both significantly impacts the panel’s performance and cost. Common facing materials include steel and aluminum, each with its advantages in terms of durability, aesthetics, and cost. Core materials, on the other hand, determine the panel’s thermal performance. Popular core materials include polyisocyanurate (polyiso), polyurethane (polyurethane), and extruded polystyrene (XPS).

Comparison of Insulated Metal Roofing Panel Types

The following table compares four common types of insulated metal roofing panels based on their R-value, weight, estimated cost, and typical lifespan. Note that costs and lifespans can vary depending on specific manufacturers, panel configurations, and installation practices.

| Panel Type | Core Material | Facing Material | R-Value (per inch) | Weight (lbs/sq ft) | Estimated Cost ($/sq ft) | Typical Lifespan (years) |

|---|---|---|---|---|---|---|

| Polyiso-Steel | Polyisocyanurate | Steel | 6-8 | 2-3 | 3-5 | 30-50 |

| Polyurethane-Steel | Polyurethane | Steel | 6-7 | 2-3 | 4-6 | 30-50 |

| Polyiso-Aluminum | Polyisocyanurate | Aluminum | 6-8 | 1.5-2.5 | 5-7 | 40-60 |

| XPS-Steel | Extruded Polystyrene | Steel | 4-5 | 1.5-2 | 2-4 | 20-30 |

Thermal Performance and Energy Efficiency, Insulated metal roofing panels

The R-value is a critical indicator of a panel’s thermal resistance. A higher R-value signifies better insulation, leading to reduced energy consumption for heating and cooling. Polyiso and polyurethane cores generally offer higher R-values compared to XPS, resulting in improved energy efficiency. For example, a building using polyiso-steel panels in a cold climate could see significant reductions in heating costs compared to a building with XPS-steel panels. The choice of core material directly impacts the building’s overall energy performance.

Durability and Longevity Under Various Weather Conditions

The durability and longevity of insulated metal roofing panels depend on both the core and facing materials, as well as the quality of the manufacturing and installation. Steel facings are generally more resistant to dents and scratches than aluminum, but aluminum offers superior corrosion resistance, particularly in coastal environments. All types of panels can withstand high winds, but proper installation is critical. Panels with higher R-values may offer better protection against extreme heat and cold, minimizing temperature fluctuations within the building. For example, polyiso panels have demonstrated excellent performance in regions experiencing extreme temperature variations. Heavy snowfall is generally well-managed by all panel types, provided proper slope and drainage are considered during installation.

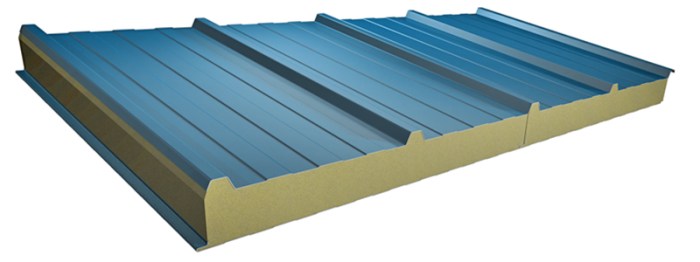

Installation Methods and Best Practices

Source: azroof.com

Installing insulated metal roofing panels requires careful planning and execution to ensure a long-lasting, leak-proof roof. This process involves several key steps, from preparing the roof deck to final sealing, and understanding best practices will significantly impact the longevity and performance of your roof.

Proper installation is crucial for maximizing the benefits of insulated metal roofing, including energy efficiency and weather protection. Ignoring best practices can lead to leaks, premature panel failure, and increased maintenance costs. This section details the step-by-step process, emphasizing critical points for a successful installation.

Roof Deck Preparation

Before installing any panels, the existing roof deck must be thoroughly prepared. This ensures a stable and even surface for panel installation, preventing issues later on. A poorly prepared deck can lead to uneven panel alignment, fastener problems, and potential leaks.

- Inspect the existing roof deck for any damage, such as rot, warping, or loose boards. Repair or replace any damaged sections.

- Clean the roof deck thoroughly, removing any debris, dirt, or loose materials. This ensures proper adhesion of any underlayment.

- Ensure the roof deck is structurally sound and able to support the weight of the insulated metal panels. Consult a structural engineer if necessary.

- If required, install a suitable underlayment, such as ice and water shield, to protect against moisture intrusion.

Panel Alignment and Fastening

Accurate panel alignment and proper fastening are essential for a watertight roof. Incorrect fastening can lead to panel movement, leaks, and compromised structural integrity. Using the correct fasteners and techniques is crucial for a long-lasting roof.

- Begin installation at the lowest point of the roof, working your way up. This ensures proper water runoff.

- Align the first panel carefully, ensuring it is straight and level. Use a chalk line or laser level for accuracy.

- Secure the panels using the recommended fasteners and spacing. Over-fastening can damage the panels, while under-fastening can lead to movement and leaks. Follow the manufacturer’s instructions for fastener type and placement.

- Overlap panels according to manufacturer’s specifications, ensuring a watertight seal. This typically involves overlapping the side laps and end laps.

- Use self-tapping screws designed for metal roofing. These screws should be long enough to penetrate the panel and the roof deck securely.

Sealing and Flashing

Proper sealing and flashing are critical to prevent water penetration. Careful attention to detail in these areas will significantly enhance the longevity and performance of the roofing system. Using the right sealant and flashing materials is essential for long-term protection.

- Apply sealant to all seams and overlaps to create a watertight seal. Use a high-quality sealant specifically designed for metal roofing.

- Install flashing around vents, chimneys, and other roof penetrations. This prevents water from entering the roof system.

- Ensure all flashings are properly sealed and secured to prevent leaks.

Ventilation

Adequate ventilation is crucial for preventing moisture buildup within the roof system. This helps to extend the life of the roofing materials and prevent problems such as mold and mildew. Proper ventilation ensures a healthy and long-lasting roof.

Insulated metal roofing panels, while offering excellent insulation, can still trap moisture if ventilation is inadequate. Sufficient ventilation allows for the escape of warm, moist air, preventing condensation and ice dam formation.

Essential Tools and Equipment

Having the right tools and equipment is essential for a smooth and efficient installation. The proper tools make the job easier and help ensure a high-quality installation.

- Measuring tape

- Chalk line or laser level

- Drill with appropriate drill bits

- Screwdriver (impact driver recommended)

- Safety equipment (hard hat, safety glasses, gloves)

- Metal snips or shears

- Sealant and caulking gun

- Ladder and scaffolding (if necessary)

Installation Process Flowchart

A visual representation of the installation process can be helpful. The following describes a simplified flowchart. Remember to always consult the manufacturer’s instructions for specific details.

[Imagine a flowchart here. The flowchart would begin with “Roof Deck Preparation,” branching to “Inspect and Repair,” “Clean,” and “Install Underlayment.” This would lead to “Panel Installation,” branching to “Panel Alignment,” “Fastening,” and “Overlapping.” Next would be “Sealing and Flashing,” followed by “Final Inspection.” Each step would have a decision point for quality control and correction if necessary. The final step would be “Project Completion.”]

Cost Considerations and ROI: Insulated Metal Roofing Panels

Source: rpsmetalroofing.com

Investing in a new roof is a significant undertaking, and understanding the costs involved is crucial. Insulated metal roofing panels, while offering substantial long-term benefits, require a careful assessment of upfront expenses and projected returns. This section breaks down the cost components and explores the return on investment (ROI) you can expect.

The total cost of an insulated metal roof encompasses several factors. It’s not simply the price of the panels themselves; labor, permits, and potential unforeseen expenses also contribute to the final figure. Accurate budgeting requires a detailed understanding of these various components.

Insulated Metal Roofing Cost Breakdown

The following table provides a general estimate of the cost breakdown. Remember that actual costs can vary significantly based on factors such as location, roof size and complexity, and the specific materials chosen. It’s always best to obtain multiple quotes from reputable contractors.

| Cost Component | Cost per Square (100 sq ft) | Example for 2000 sq ft Roof | Notes |

|---|---|---|---|

| Materials (Panels, Fasteners, etc.) | $800 – $1500 | $16,000 – $30,000 | Prices greatly depend on panel type, gauge, and finish. |

| Labor (Installation, Tear-off (if needed)) | $300 – $700 | $6,000 – $14,000 | Labor costs depend on the complexity of the roof and local labor rates. |

| Permits and Inspections | $100 – $300 | $2,000 – $6,000 | Permit costs vary by location and local regulations. |

| Contingency (Unforeseen Expenses) | $100 – $200 | $2,000 – $4,000 | Always budget for unexpected issues that might arise during installation. |

| Total Estimated Cost | $1300 – $2700 | $26,000 – $54,000 | This is a broad range; obtain detailed quotes for your specific project. |

Long-Term Cost Savings

While the initial investment in insulated metal roofing is higher than some alternatives, the long-term cost savings can be substantial. These savings stem primarily from improved energy efficiency and significantly reduced maintenance needs.

The superior insulation properties of insulated metal panels reduce energy consumption for both heating and cooling. This translates directly into lower utility bills over the life of the roof. For example, a homeowner in a climate with extreme temperatures might see a reduction in annual energy costs of several hundred dollars, quickly offsetting a portion of the initial investment.

Furthermore, metal roofs are incredibly durable and require minimal maintenance. Unlike asphalt shingles, which need frequent repairs and replacements, a well-installed metal roof can last 50 years or more with little to no upkeep, saving money on costly repairs and replacements over time.

Cost Comparison with Other Roofing Materials

Comparing the initial cost of insulated metal roofing to other options such as asphalt shingles or clay tile reveals a clear difference. Asphalt shingles are typically the least expensive upfront, but their shorter lifespan (15-20 years) necessitates more frequent replacements, ultimately increasing the total cost of ownership over time. Clay tile roofs, while durable, are significantly more expensive initially and can be heavier, requiring more substantial structural support.

A hypothetical example: A 2000 sq ft roof might cost $8,000-$12,000 for asphalt shingles, $15,000-$25,000 for clay tiles, and $26,000-$54,000 for insulated metal roofing (based on the table above). However, the significantly longer lifespan and lower maintenance costs of the metal roof can make it the most cost-effective choice in the long run.

Return on Investment (ROI)

The ROI of insulated metal roofing is calculated by considering the initial cost, the lifespan of the roof, energy savings, and reduced maintenance costs. A longer lifespan and higher energy savings lead to a faster ROI. While a precise calculation requires specific data for your location and energy consumption, a well-installed insulated metal roof often provides a strong ROI within 10-15 years, and significant savings beyond that point.

For instance, consider a homeowner who saves $500 annually on energy costs due to improved insulation. Over 20 years, that’s $10,000 in savings. This, combined with the reduced maintenance costs compared to asphalt shingles, can easily offset the higher initial investment of the metal roof, resulting in a substantial positive ROI.

Maintenance and Repair

Source: tsscgroup.com

Insulated metal roofing panels, while incredibly durable, still require regular maintenance to ensure longevity and prevent costly repairs. A proactive approach to upkeep will save you time, money, and potential headaches down the line. This section details a recommended maintenance schedule, common problems, and how to address minor damage.

Maintenance Schedule

Regular inspections and cleaning are crucial for maintaining the integrity of your insulated metal roof. Neglecting these tasks can lead to premature wear and tear, potentially resulting in leaks, corrosion, and other issues. A well-maintained roof will significantly extend its lifespan and protect your investment.

- Annual Inspection: Conduct a thorough visual inspection of the entire roof at least once a year, preferably in spring or fall after seasonal changes. Look for signs of damage, such as dents, scratches, rust, loose fasteners, or missing sealant.

- Semi-Annual Cleaning: Clean the roof twice a year to remove debris, leaves, and other materials that can accumulate and trap moisture. Use a soft-bristled brush or broom and avoid harsh chemicals that could damage the coating.

- Gutter Cleaning: Keep gutters and downspouts clear of debris to prevent water from backing up onto the roof. Clogged gutters can lead to ice dams in colder climates.

- Fastener Check: Every few years, inspect all fasteners and ensure they are tight. Loose fasteners can allow water penetration.

- Sealant Inspection: Check all seams and flashings for any signs of sealant deterioration or cracking. Reapply sealant as needed.

Common Problems and Causes

Several issues can arise with insulated metal roofing panels, often stemming from improper installation, environmental factors, or lack of maintenance. Understanding these potential problems allows for preventative measures and timely repairs.

- Leaks: Leaks can be caused by damaged panels, loose fasteners, cracked sealant, or improper flashing around penetrations (chimneys, vents).

- Rust: Rust develops due to exposure to moisture and oxygen. This is more common in areas with high humidity or coastal regions.

- Dents and Scratches: Impacts from hail, falling branches, or other objects can cause dents and scratches. While largely cosmetic, these can compromise the protective coating and lead to future problems.

- Fastener Failure: Improper installation or exposure to the elements can lead to fastener failure, causing leaks and panel movement.

- Sealant Failure: Sealant degradation due to UV exposure or temperature fluctuations can lead to leaks at seams and joints.

Minor Damage Repair

Minor damage, such as dents and scratches, can often be repaired without replacing entire panels. Addressing these issues promptly prevents further damage and extends the roof’s life.

- Dents: Small dents can sometimes be pushed out from the underside of the panel using a specialized tool or a carefully applied suction cup. For larger dents, professional repair might be necessary.

- Scratches: Scratches in the paint can be touched up with a suitable paint designed for metal roofing. Always use a color-matched paint to maintain the roof’s appearance.

- Small Leaks: Small leaks around fasteners can often be sealed with a high-quality sealant designed for metal roofing. Ensure the area is clean and dry before applying the sealant.

Damaged Panel Replacement

Replacing damaged panels requires more effort and specialized tools. This is best handled by professionals unless you have significant experience with roofing work.

- Tools Required: Safety equipment (harness, gloves), pry bar, tin snips, sealant, new panel, screws, drill, and possibly a roofing lift.

- Replacement Process: Carefully remove the damaged panel using a pry bar, being careful not to damage adjacent panels. Install the new panel, ensuring proper alignment and secure fastening. Seal all seams and joints with appropriate sealant.

Environmental Impact and Sustainability

Source: nucorbuildingsystems.com

Insulated metal roofing panels offer a compelling blend of performance and environmental considerations. While their manufacturing process involves energy consumption and resource use, their longevity, recyclability, and energy-saving properties contribute significantly to a more sustainable building approach. Let’s examine the environmental footprint of these panels in detail.

The environmental impact of insulated metal roofing panels stems primarily from the manufacturing process and the embodied energy of their constituent materials. Steel production, a key component, is energy-intensive, requiring significant amounts of electricity and fossil fuels. The manufacturing of the insulation core, typically polyurethane or polyisocyanurate, also consumes energy and involves the use of chemicals. Transportation from manufacturing facilities to installation sites adds to the overall carbon footprint. However, the environmental benefits of these panels often outweigh these initial impacts.

Manufacturing and Installation Energy Consumption

The energy used to produce insulated metal roofing panels is a significant factor in their overall environmental impact. The steel production process, involving mining, smelting, and rolling, consumes substantial energy. The type of steel used (e.g., recycled content) and the efficiency of the manufacturing process directly influence the overall energy consumption. Similarly, the production of the insulation core material requires energy and resources. Transportation of materials to the manufacturing facility and then to the construction site adds to the overall energy expenditure. While precise figures vary based on manufacturing methods and material sources, lifecycle assessments (LCAs) are available from various manufacturers that provide a comprehensive overview of the energy consumed throughout the product’s life.

Comparison with Other Roofing Materials

Compared to other roofing materials, insulated metal roofing panels often demonstrate a favorable environmental profile over their lifespan. For instance, asphalt shingles, a common alternative, require significant energy for extraction, processing, and transportation, and have a shorter lifespan, leading to more frequent replacements. Clay and concrete tiles, while durable, have high embodied energy due to their manufacturing process and transportation needs. The superior lifespan of insulated metal panels, typically 50 years or more, reduces the frequency of replacements, mitigating the environmental impact associated with material extraction and disposal.

Recycled Content and Recyclability

A significant advantage of insulated metal roofing panels is their potential for incorporating recycled content and their recyclability at the end of their lifespan. Many manufacturers utilize a substantial percentage of recycled steel in their products, reducing the demand for virgin materials. Furthermore, the panels themselves are largely recyclable. At the end of their service life, the steel and insulation components can be separated and recycled, minimizing landfill waste and conserving resources. The recyclability rate depends on the efficiency of the recycling infrastructure in a given region, but the potential for significant resource recovery is substantial.

Sustainability Features and Green Building Practices

Insulated metal roofing panels contribute to green building practices in several ways. Their superior thermal performance reduces the need for heating and cooling, lowering energy consumption in buildings. This energy efficiency translates to reduced greenhouse gas emissions and lower operational costs. Their long lifespan minimizes the need for frequent replacements, further reducing environmental impact. The use of recycled materials and the panels’ recyclability further enhance their sustainability profile, aligning with principles of resource conservation and waste reduction. Several green building rating systems, such as LEED, recognize the environmental benefits of insulated metal roofing panels, awarding points for their use in sustainable construction projects. For example, a building incorporating insulated metal roofing might qualify for LEED points related to energy efficiency, material reuse, and waste reduction.

Final Conclusion

Source: lowes.com

Choosing insulated metal roofing panels represents a significant investment, but one that offers substantial long-term benefits. From enhanced energy efficiency and reduced maintenance to increased durability and a longer lifespan, these panels provide a smart and sustainable solution for various roofing applications. By understanding the various factors discussed—types, installation, cost, maintenance, and environmental impact—you can confidently select the right panels for your project and enjoy the numerous advantages they offer.