Mini Orb Roofs A Design Guide

Mini orb roofs: They sound futuristic, right? These dome-like structures offer a unique blend of modern aesthetics and practical functionality. This guide dives into the design, construction, materials, and maintenance of mini orb roofs, exploring their various applications and helping you decide if this striking roofing style is right for your project. We’ll cover everything from choosing the right materials to understanding the installation process and addressing common concerns.

We’ll explore the different design variations, from sleek metal orbs to more rustic composite options, and delve into the construction techniques that ensure durability and weather resistance. We’ll also look at the cost implications and the environmental impact of various materials, helping you make informed decisions throughout the process.

Defining “Mini Orb Roof”

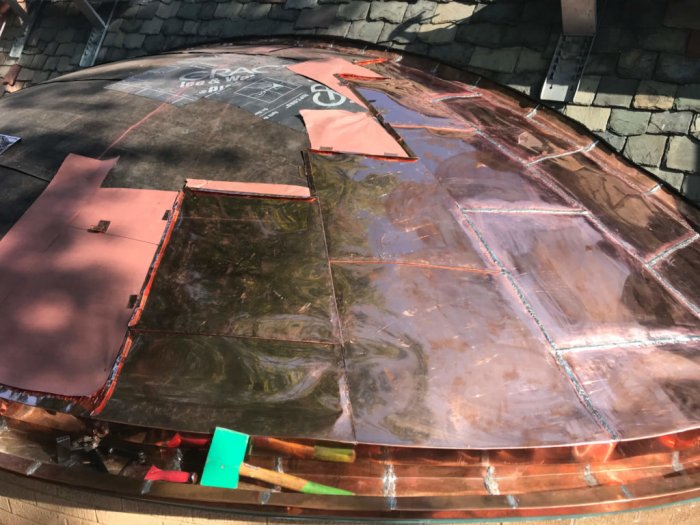

Source: tileandslateroof.com

A mini orb roof, also sometimes called a mini dome roof or a small geodesic dome, is a type of roofing structure characterized by its spherical or semi-spherical shape and its relatively small size compared to larger geodesic domes. It’s constructed using a framework of interconnected triangular elements, often made from lightweight materials, creating a strong and aesthetically pleasing structure. Mini orb roofs are typically used for smaller structures like garden sheds, gazebos, or small additions to existing buildings.

Mini orb roofs offer a unique blend of structural integrity and visual appeal. Their curved shape allows for efficient shedding of water and snow, while the triangular framework distributes loads effectively, resulting in a robust and durable roof. The relatively small size makes them suitable for a variety of applications where a full-sized geodesic dome would be impractical.

Mini Orb Roof Design and Material Variations

Mini orb roof designs vary significantly depending on the intended application and aesthetic preferences. The number of triangular panels, the overall curvature, and the height of the dome can all be adjusted to achieve different looks and functionalities. Materials used in construction also exhibit considerable diversity. Common framing materials include lightweight steel, aluminum, or even treated lumber for smaller, less demanding applications. The covering can range from traditional roofing materials like asphalt shingles or metal sheeting to more modern options like polycarbonate panels for greater light transmission. Some designs might even incorporate flexible materials stretched over the framework for a more seamless, contemporary look. The choice of materials impacts the overall weight, cost, and lifespan of the structure.

Comparison with Other Roofing Styles

Mini orb roofs differ significantly from traditional gable or hip roofs. Unlike the straight lines and flat planes of gable and hip roofs, mini orb roofs utilize a curved, three-dimensional structure. This curved shape provides a superior strength-to-weight ratio and better resistance to high winds and snow loads compared to conventional designs. Compared to other curved roofing styles like barrel vaults, mini orb roofs are generally more adaptable to smaller spaces and offer greater design flexibility due to the modular nature of their triangular framework. The modularity also allows for customization of size and shape to fit specific needs, a feature lacking in many other roofing solutions. While potentially more expensive than simpler roofing styles in terms of initial construction cost, the long-term durability and resistance to harsh weather conditions can often offset this higher initial investment.

Design and Construction

Source: tileandslateroof.com

Building a mini orb roof involves careful planning and execution to ensure structural integrity and weather resistance. The design process considers the desired size, the materials used, and the anticipated environmental loads. Construction techniques vary depending on the chosen materials and the level of complexity desired.

Design Considerations

Mini orb roof design starts with determining the desired diameter and overall height. This dictates the necessary framework size and the quantity of materials required. Load-bearing capacity is crucial; the design must withstand the weight of the roofing material, snow loads (depending on climate), and wind pressure. Accurate calculations are essential to prevent structural failure. Weather resistance is equally important; the chosen materials should be durable and able to withstand rain, snow, and extreme temperatures. Proper sealing and waterproofing are key elements in achieving this. For example, a mini orb roof designed for a coastal area would require materials that resist salt corrosion and strong winds, differing from a design for a dry, desert climate.

Construction Methods and Materials

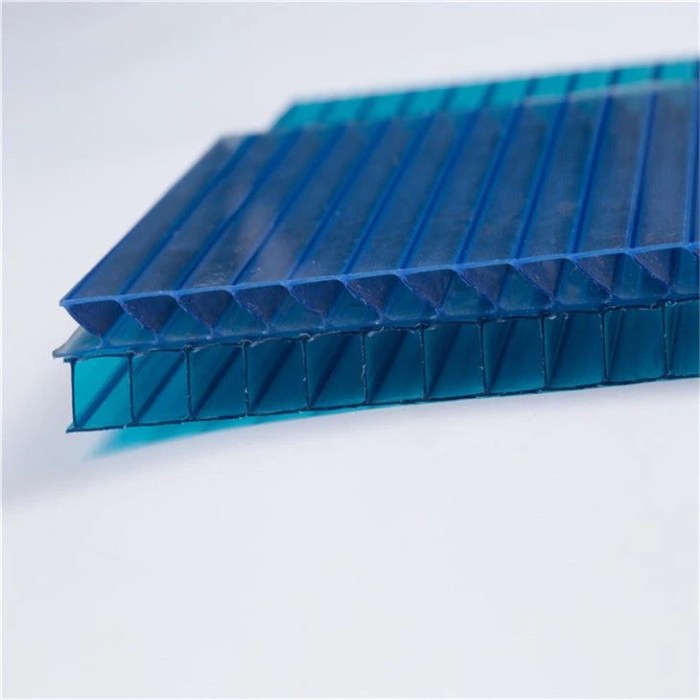

Several methods exist for constructing mini orb roofs. One common approach involves using a framework of lightweight yet strong materials like treated lumber or metal tubing. This framework forms the underlying structure onto which the roofing material is attached. Popular roofing materials include polycarbonate sheets (for their transparency and durability), corrugated metal (for strength and longevity), or even thatch (for a more rustic aesthetic, though this choice demands careful consideration of weather resistance). The chosen material impacts the design; for instance, polycarbonate sheets require a more precise framework to maintain their shape and prevent sagging. Another method involves using prefabricated geodesic dome kits which simplify construction, offering pre-cut components and detailed instructions. These kits often come with specific roofing materials.

Mini Orb Roof Installation: A Step-by-Step Guide

Before beginning any installation, always consult local building codes and regulations. Proper permits may be required.

| Step Number | Task | Tools Required | Safety Precautions |

|---|---|---|---|

| 1 | Prepare the foundation. Ensure a level and stable base. | Level, measuring tape, shovel, concrete (if needed) | Wear appropriate footwear and safety glasses. |

| 2 | Assemble the framework according to the design plans. | Screws, bolts, wrenches, drill, saw (if necessary) | Use appropriate safety gear for power tools. |

| 3 | Attach the roofing material to the framework, ensuring proper overlap and sealing. | Screws, sealant, roofing nails, utility knife | Wear gloves to protect your hands and use caution with sharp tools. |

| 4 | Inspect for any gaps or leaks. Seal as needed. | Sealant, caulking gun | Work carefully to prevent sealant from dripping onto other surfaces. |

| 5 | Final inspection. Ensure all connections are secure and weatherproof. | Visual inspection | Ensure structural stability before use. |

Materials and Costs

Source: hsoubcdn.com

Building a mini orb roof involves careful consideration of materials and their associated costs. The choice of materials significantly impacts both the final aesthetic and the overall budget. Understanding the properties and price points of various options is crucial for successful project planning.

Choosing the right materials for your mini orb roof is a balancing act between cost, durability, and aesthetics. Let’s examine some common options and their respective price ranges.

Common Mini Orb Roof Materials

The most common materials used in mini orb roof construction are polycarbonate, fiberglass, and metal. Polycarbonate offers excellent light transmission and impact resistance, but it can be more expensive than other options. Fiberglass is a lighter and more affordable alternative, though it’s less durable and may not offer the same level of light transmission. Metal roofing, typically aluminum or steel, is highly durable and long-lasting but can be more costly upfront and may require more maintenance. Each material presents a unique set of advantages and disadvantages impacting both initial investment and long-term maintenance.

Cost Comparison of Mini Orb Roof Materials

The cost of materials varies greatly depending on the size and complexity of the structure, the chosen material, and regional pricing. As a general estimate, a small mini orb roof (approximately 100 square feet) might range from $500 to $2000 for materials alone, depending on the material chosen. Polycarbonate tends to be at the higher end of this range, while fiberglass sits in the middle, and metal can vary depending on the type and finish. These figures are estimates and should be verified with local suppliers. For example, a simple fiberglass structure might cost around $700-$1200 in materials, while a similar-sized polycarbonate structure could easily reach $1500-$2000. Metal roofing, while potentially more durable, can also range within this spectrum or even exceed it depending on the type of metal and any additional features.

Cost Breakdown for a Typical Mini Orb Roof Installation

A realistic cost breakdown for a typical mini orb roof installation should account for materials, labor, and permits. Let’s consider a hypothetical 100 square foot mini orb roof using polycarbonate.

| Cost Item | Estimated Cost |

|---|---|

| Materials (Polycarbonate sheets, framing, fasteners) | $1500 – $2000 |

| Labor (Installation, site preparation) | $1000 – $2000 |

| Permits (Building permits, inspections) | $200 – $500 |

| Total Estimated Cost | $2700 – $4500 |

Note: This cost breakdown is an estimate and can vary significantly depending on location, labor rates, and specific project requirements. Always obtain multiple quotes from reputable contractors before starting your project.

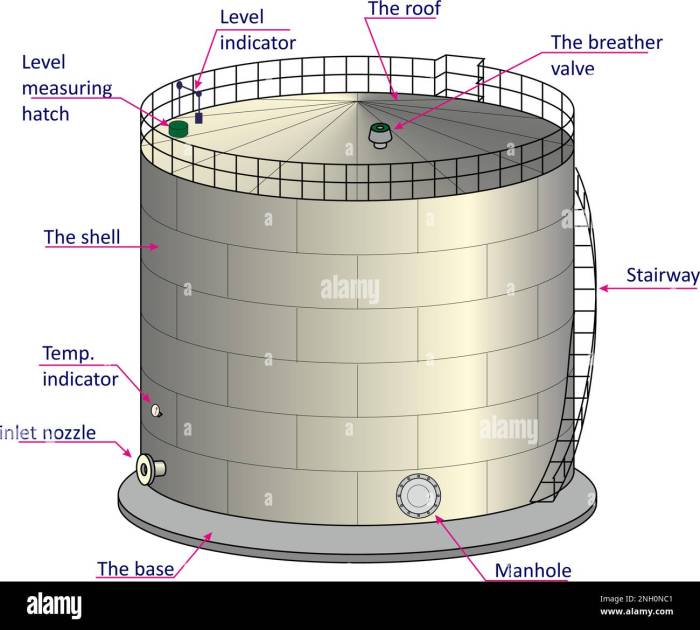

Aesthetics and Applications

Source: vecteezy.com

Mini orb roofs offer a unique blend of modern aesthetics and practicality, making them a versatile choice for a range of architectural styles and building types. Their smooth, curved surfaces create a visually striking element, adding a touch of contemporary flair while maintaining a level of understated elegance. The adaptability of their design allows for seamless integration into both traditional and modern building designs.

The visual impact of a mini orb roof is largely dependent on factors such as the size and curvature of the orbs, the roofing material used, and the overall design of the building. A smaller, more subtly curved orb might complement a traditional farmhouse, while larger, more pronounced orbs can become a striking focal point in a contemporary structure. The interplay of light and shadow across the curved surfaces adds another layer of visual interest, enhancing the overall aesthetic appeal.

Mini Orb Roof Applications in Different Building Types

Mini orb roofs are finding increasing applications across various sectors. Their adaptability and relatively straightforward construction make them suitable for diverse projects. This versatility extends to residential, commercial, and industrial buildings, showcasing their adaptability to different needs and budgets.

- Residential Buildings: Mini orb roofs can be incorporated into extensions, garages, porches, or even as the main roof of smaller houses. Their unique shape can add a modern twist to traditional homes or serve as a striking feature in contemporary designs. Imagine a small, modern cabin nestled in a wooded area, topped with a mini orb roof that seamlessly blends with the natural surroundings. The curved surfaces could be clad in natural wood shingles, echoing the texture and color of the surrounding trees.

- Commercial Buildings: In commercial settings, mini orb roofs can be used for canopies over entrances, walkways, or outdoor seating areas. They offer a stylish and functional solution for protecting these spaces from the elements. Think of a small boutique shop with a stylish mini orb roof canopy above the entrance, creating a welcoming and visually appealing focal point.

- Industrial Buildings: While less common as a primary roofing solution in large-scale industrial projects, mini orb roofs can be effectively utilized for smaller structures within an industrial complex, such as storage sheds, maintenance facilities, or even employee break rooms. The durability of the materials used in construction makes them suitable for withstanding harsh weather conditions.

Building Types Well-Suited for Mini Orb Roofs

The unique characteristics of mini orb roofs make them particularly well-suited for certain building types. Their size and design lend themselves to specific applications, maximizing both aesthetic and functional benefits.

- Small residential additions or outbuildings.

- Gazebos and garden structures.

- Canopies and covered walkways.

- Small commercial structures such as kiosks or retail spaces.

- Industrial sheds or utility buildings.

Maintenance and Durability

Source: dreamstime.com

Mini orb roofs, while offering a unique aesthetic and structural advantage, require consistent maintenance to ensure their longevity and prevent costly repairs. Regular upkeep protects your investment and maintains the roof’s structural integrity and visual appeal. Ignoring maintenance can lead to premature degradation and significantly shorten the lifespan of your roof.

Regular inspections and prompt attention to minor issues are key to preventing major problems. This proactive approach minimizes long-term expenses and ensures the continued performance and beauty of your mini orb roof.

Routine Maintenance Tasks

A yearly inspection is recommended, ideally during both spring and autumn. This allows for the identification of any potential issues before they escalate. These inspections should include checking for signs of wear and tear, such as loose or damaged panels, sealant degradation, and any signs of rust or corrosion, especially in coastal areas or regions with harsh winters. Cleaning the roof surface to remove debris, leaves, and moss is also crucial. This prevents build-up that can trap moisture and damage the roofing material. For higher roofs, professional cleaning services are recommended for safety reasons. Finally, regularly check the drainage system to ensure water flows freely away from the structure. Blocked gutters can lead to water damage and structural problems.

Common Problems and Solutions

Several common problems can affect mini orb roofs. These often stem from improper installation, material degradation, or environmental factors.

Panel Damage and Leaks

Damaged or cracked panels are a significant concern. Repairing minor damage might involve using specialized sealants or patching materials. However, severely damaged panels usually require replacement. Prompt action prevents water ingress, which can lead to costly structural damage. Regular inspections are vital in catching small cracks before they become larger problems.

Sealant Degradation

Over time, the sealant between panels can degrade, losing its water-resistant properties. This often shows as discoloration or cracking around the panel edges. Resealing is a straightforward solution that significantly improves the roof’s water tightness. This process is best done by a professional to ensure proper application and longevity.

Rust and Corrosion

In coastal or humid climates, rust and corrosion can affect metal components of the mini orb roof. Regular cleaning and application of rust inhibitors can help prevent or mitigate this problem. If significant corrosion is found, replacement of affected parts is necessary. Choosing corrosion-resistant materials during the initial construction phase is highly advisable.

Expected Lifespan

The lifespan of a mini orb roof depends heavily on several factors, including material quality, installation quality, and environmental conditions.

Lifespan Under Different Conditions

Under ideal conditions (mild climate, minimal exposure to extreme weather events), a well-maintained mini orb roof can last 30-50 years or more. However, in harsh environments with frequent extreme weather (high winds, heavy snow, intense sun), the lifespan might be reduced to 20-30 years. Coastal areas, due to salt spray corrosion, generally have a shorter lifespan. For example, a mini orb roof constructed using high-quality, corrosion-resistant materials in a dry, desert climate might easily surpass the 50-year mark, while a roof in a coastal area with frequent hurricanes might require more frequent maintenance and replacement of components after 20 years. Regular maintenance significantly extends the lifespan regardless of the environment. Investing in high-quality materials from the outset also pays dividends in terms of longevity.

Environmental Impact: Mini Orb Roof

Source: uzaykon.com

Mini orb roofs, like any construction project, have an environmental footprint. The impact varies significantly depending on the materials chosen and the construction practices employed. Understanding this impact is crucial for making informed decisions that minimize the negative effects on the environment.

The environmental impact of a mini orb roof is largely determined by the materials used in its construction. Different materials have varying levels of embodied energy (the energy used to extract, process, transport, and manufacture them), carbon emissions during production and transportation, and end-of-life disposal impacts. Sustainable choices can significantly reduce the overall environmental footprint.

Material-Specific Environmental Impacts

The choice of roofing material significantly impacts the environmental performance of a mini orb roof. For example, using recycled materials reduces the demand for virgin resources and minimizes landfill waste. Conversely, materials requiring high energy input for manufacturing, like some plastics, can increase the overall carbon footprint. Metals such as aluminum or steel have higher embodied energy compared to some plastics or composite materials, but can be recycled more easily at the end of their lifespan. Consideration of the material’s lifecycle, from cradle to grave, is essential for minimizing its environmental impact.

Energy Efficiency of Mini Orb Roofs

Mini orb roofs can contribute to energy efficiency through their design and the materials used. Proper insulation within the structure can significantly reduce heat transfer, lowering the need for heating and cooling, thereby decreasing energy consumption. The shape of the roof itself can also influence energy performance, with specific designs optimizing solar gain in winter and minimizing solar heat absorption in summer. A comparison to traditional gable or hip roofs would show varying energy efficiency levels depending on factors such as climate, insulation, and window placement. For instance, a well-insulated mini orb roof in a hot climate might significantly outperform a poorly insulated traditional roof in reducing cooling loads.

Sustainable Practices in Mini Orb Roof Design and Installation

Sustainable practices are key to minimizing the environmental impact of mini orb roof construction. These include using recycled or sustainably sourced materials, optimizing the design for passive solar heating and cooling, minimizing waste during construction, and employing environmentally friendly construction techniques. For example, selecting materials with high recycled content reduces the demand for new resources and lowers associated emissions. Implementing efficient insulation reduces energy consumption throughout the roof’s lifespan. Careful planning and precision cutting during construction can minimize material waste, further contributing to environmental sustainability. The use of locally sourced materials reduces transportation emissions. The selection of durable materials extends the lifespan of the roof, delaying the need for replacement and associated environmental impacts.

Illustrative Examples

Source: tileandslateroof.com

Let’s explore three distinct mini orb roof designs to illustrate the versatility and adaptability of this architectural feature. These examples showcase different material choices and highlight the impact of design decisions on the overall aesthetic and functionality.

Mini Orb Roof Design 1: The Modern Metal Marvel

This design features a sleek, 10-foot diameter mini orb roof constructed from polished stainless steel. The spherical structure is supported by a simple, yet elegant, framework of powder-coated black steel. The stainless steel’s reflective surface creates a dynamic interplay of light and shadow, particularly striking in sunny environments. The smooth, seamless surface of the stainless steel contrasts sharply with the sharp lines of the supporting structure, giving the overall design a clean, contemporary feel. This mini orb roof would be ideal for a modern patio or as a striking feature over a small outdoor seating area. The high reflectivity of the stainless steel helps to mitigate heat gain, a significant advantage in warmer climates.

Mini Orb Roof Design 2: The Rustic Charm of Cedar

In contrast to the sleek metal design, this example uses western red cedar shingles to create a warm, rustic feel. This 8-foot diameter mini orb roof sits atop a charming gazebo, blending seamlessly with its natural surroundings. The cedar shingles are carefully applied, overlapping to create a textured surface that evokes a sense of handcrafted artistry. The natural variations in the cedar’s color and grain add visual interest and warmth, contrasting beautifully with the more structured lines of the gazebo’s supporting beams. This design is perfect for gardens or outdoor spaces where a more natural, organic aesthetic is desired. The cedar’s natural resistance to decay makes it a durable choice for outdoor applications, although regular maintenance is still recommended.

Mini Orb Roof Design 3: The Contemporary Composite Solution

This design utilizes a composite material – specifically, a fiberglass-reinforced polymer – to create a lightweight yet durable 12-foot diameter mini orb roof for a small poolside cabana. The composite material is molded into a smooth, seamless surface, painted a vibrant turquoise to complement the surrounding pool and landscaping. The color remains consistent and vibrant, unlike some natural materials, which fade or change with exposure to the elements. The composite material offers significant advantages in terms of weight and ease of installation, reducing the complexity and cost associated with construction. The smooth surface is easy to clean and maintain, and the color is resistant to fading and chipping. This example highlights how composite materials can provide a balance between aesthetic appeal and practical functionality.

Conclusive Thoughts

Source: alamy.com

Mini orb roofs represent a fascinating intersection of form and function. Their distinctive shape offers a visually appealing alternative to traditional roofing styles while providing excellent weather protection. By carefully considering design, materials, and installation, you can create a durable, aesthetically pleasing, and potentially environmentally friendly structure. This guide provides a solid foundation for understanding and implementing this unique roofing solution, allowing you to confidently navigate the design and construction process.