Onduline Cladding A Comprehensive Guide

Onduline cladding offers a unique blend of affordability, durability, and ease of installation, making it a compelling choice for various building projects. This guide dives deep into everything you need to know about Onduline cladding, from its material properties and installation techniques to its aesthetic appeal and long-term value. We’ll cover everything from choosing the right color to tackling common installation challenges, ensuring you’re well-equipped to make informed decisions.

Whether you’re a seasoned professional or a DIY enthusiast, understanding the nuances of Onduline cladding is key to a successful project. We’ll explore its composition, compare it to other cladding materials, and guide you through the installation process step-by-step. We’ll also look at design options, maintenance strategies, and cost considerations, painting a complete picture of this versatile cladding solution.

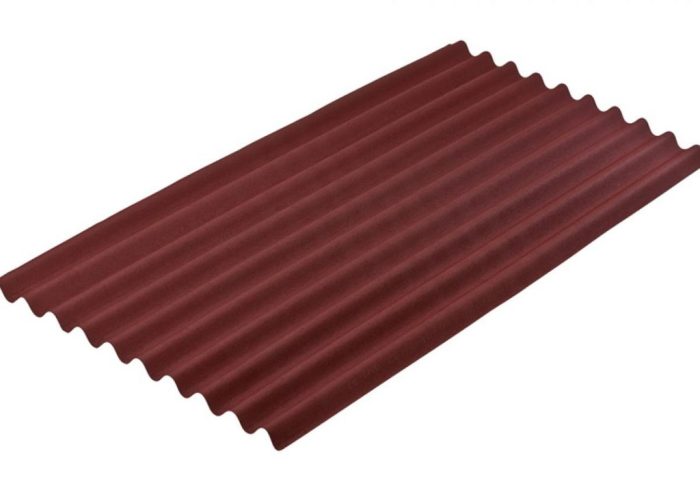

Onduline Cladding

Source: galileodc.com

Onduline cladding is a popular roofing and wall covering material known for its affordability and ease of installation. This section delves into the material properties of Onduline cladding, exploring its composition, manufacturing, properties compared to other materials, and environmental impact.

Onduline Cladding Composition and Manufacturing

Onduline cladding is primarily composed of a mixture of cellulose fibers, bitumen, and mineral fillers. The cellulose fibers provide structural strength, while the bitumen acts as a binder and waterproofing agent. Mineral fillers, such as talc or limestone, are added to improve the material’s dimensional stability and fire resistance. The manufacturing process involves mixing these ingredients, forming them into sheets, and then curing them under controlled conditions to create the final product. This involves several steps, including mixing, forming, curing, and cutting to size. The process is designed to create a lightweight yet durable sheet material.

Physical Properties Compared to Other Cladding Materials

Onduline cladding’s physical properties differ significantly from other common cladding materials. The following table summarizes a comparison:

| Property | Onduline | Wood | Metal | Vinyl |

|---|---|---|---|---|

| Weight (per sq ft) | Lightweight | Medium to Heavy | Medium to Heavy | Lightweight |

| Durability (Resistance to Impact, Weather) | Moderate | High (depending on type) | High | High |

| Lifespan (Years) | 15-20 | 20-50+ (depending on type and maintenance) | 30-50+ | 20-30 |

| Cost (per sq ft) | Low | Medium to High | Medium to High | Medium |

*Note: These values are approximate and can vary depending on specific product types and conditions.*

Environmental Impact of Onduline Cladding

The environmental impact of Onduline cladding production and disposal should be considered. The manufacturing process consumes energy and resources, and the material contains bitumen, a petroleum-derived product. However, Onduline is recyclable in some regions. Responsible disposal methods are crucial to minimize environmental impact. Furthermore, the lightweight nature of Onduline can reduce transportation costs and emissions compared to heavier cladding materials. The long-term environmental impact depends heavily on responsible manufacturing practices and end-of-life management.

Onduline Cladding

Source: theperfect.in

Onduline cladding offers a lightweight, durable, and aesthetically pleasing alternative to traditional cladding materials. Its ease of installation makes it a popular choice for DIY projects and professional applications alike. This section details the installation process, best practices, and common challenges you might encounter.

Onduline Cladding Installation: A Step-by-Step Guide

Proper installation is crucial for ensuring the longevity and effectiveness of your Onduline cladding. This step-by-step guide will walk you through the process, from substrate preparation to final fastening.

- Substrate Preparation: Begin by ensuring your substrate is clean, dry, and structurally sound. Any loose debris, old paint, or damaged areas must be addressed before installation. This might involve cleaning, repairing, or even replacing sections of the substrate. A level substrate is essential for a professional-looking finish.

- Underlayment (Optional but Recommended): For added protection against moisture and improved insulation, consider using an appropriate underlayment. This will create a smoother surface and help prevent damage to the Onduline cladding.

- Starting the First Row: Begin installation at the bottom of the wall, ensuring the first row is perfectly level. Use appropriate spacing between the first row of cladding sheets.

- Overlapping Sheets: Each subsequent row of Onduline cladding sheets should overlap the previous row, typically by a specified amount indicated in the manufacturer’s instructions. This overlap ensures watertightness.

- Fastening: Secure each sheet using the recommended Onduline fasteners. Avoid over-tightening, which could damage the sheets. Ensure fasteners are correctly positioned to avoid compromising the watertight seal.

- Cutting and Finishing: Use sharp shears or a utility knife to cut Onduline cladding to size for corners, windows, and other features. Ensure all cuts are clean and straight to maintain a neat appearance.

- Final Inspection: Once installation is complete, inspect the entire cladding system for any gaps, loose fasteners, or damaged sheets. Address any issues promptly.

Onduline Cladding Fastening Techniques

Proper fastening is vital for a secure and weatherproof installation. The illustration below describes the ideal fastening pattern and techniques.

Imagine a single Onduline sheet. Fasteners should be placed approximately every 30-40cm along the top and bottom edges, and every 60-80cm along the vertical edges. This spacing provides sufficient support without over-fastening. The fasteners should be driven straight and firmly, but not excessively tight, to avoid puncturing or cracking the Onduline sheet. A slight curve in the sheet should be accounted for, ensuring the fastener is driven in securely at all points of contact. The manufacturer’s recommended fastener type and spacing should always be followed.

Substrate Preparation Best Practices

Preparing the substrate correctly is a crucial first step. Neglecting this step can lead to issues such as premature cladding failure or water damage.

Thorough cleaning is essential. Remove all loose debris, dirt, old paint, and any other material that might compromise the bond between the cladding and the substrate. Repair any damaged areas of the substrate, ensuring a smooth and level surface. For wooden substrates, treat for rot and pests. For masonry substrates, address any loose mortar or crumbling sections. Consider using a primer for improved adhesion, especially on smooth or porous surfaces.

Common Onduline Cladding Installation Challenges and Solutions

While relatively straightforward, Onduline cladding installation can present certain challenges.

- Uneven Substrate: An uneven substrate can lead to difficulties in achieving a neat and professional finish. Solution: Address unevenness before installation by leveling the substrate with appropriate materials.

- Incorrect Fastening: Over-tightening or incorrect fastener placement can damage the Onduline sheets and compromise water tightness. Solution: Follow the manufacturer’s instructions carefully and use the correct fasteners.

- Weather Conditions: Extreme weather conditions (high winds, heavy rain) can make installation difficult and potentially damage the cladding. Solution: Schedule installation for favorable weather conditions.

- Cutting Accuracy: Improper cutting can lead to gaps and an unprofessional look. Solution: Use sharp tools and measure carefully.

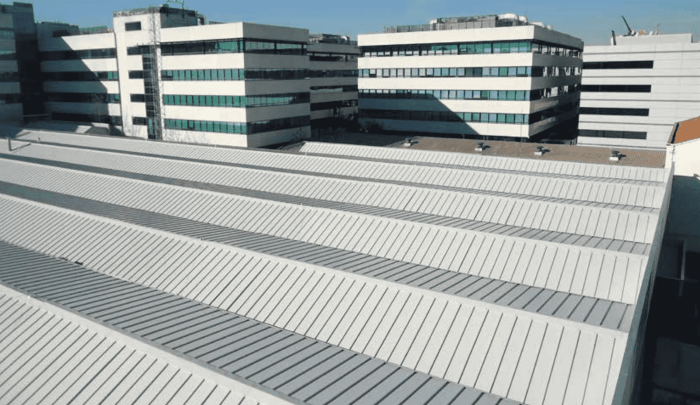

Onduline Cladding

Source: optimole.com

Onduline cladding offers a versatile and attractive exterior solution for a variety of building types. Its lightweight nature and ease of installation make it a popular choice for both residential and commercial projects, while its durability and weather resistance ensure long-lasting performance. This section delves into the design and aesthetic possibilities offered by Onduline cladding.

Design Options and Styles

Onduline cladding provides considerable design flexibility. The material’s ability to be shaped and installed in various patterns allows for the creation of unique and visually appealing facades. For instance, horizontal installation creates a clean, modern look, while vertical installation can lend a more traditional feel. Overlapping profiles can add texture and depth, while using different colors or patterns can create striking visual effects. The flexibility of the material also allows for curved applications, adding a unique architectural element to any project.

Color Choices and Finishes

Onduline cladding is available in a range of colors and finishes to complement various architectural styles and personal preferences. Popular choices often include earthy tones like browns, greens, and greys, which blend seamlessly with natural surroundings. However, bolder colors are also available for those seeking a more contemporary or striking aesthetic. Finishes may include matte, textured, or even slightly glossy options, each impacting the overall visual effect. The specific color palette and finish options may vary depending on the region and supplier.

Onduline Cladding in Various Architectural Styles

Onduline’s adaptability makes it suitable for integration into a diverse range of architectural styles.

- Modern Architecture: The clean lines and sleek profiles of Onduline cladding can perfectly complement modern designs. Imagine a minimalist home with a flat roof, clad in dark grey Onduline, creating a sophisticated and contemporary look.

- Rustic Architecture: Earth-toned Onduline cladding, perhaps in a textured finish, can beautifully enhance the charm of a rustic cabin or farmhouse. The natural look of the material complements wood and stone elements, creating a harmonious blend of materials.

- Traditional Architecture: With careful color selection and installation techniques, Onduline can even be incorporated into more traditional architectural styles. For example, a home with a steeply pitched roof clad in a warm brown Onduline can create a classic and inviting appearance.

Enhancing Visual Appeal

Onduline cladding can significantly enhance a building’s visual appeal in several ways. Its lightweight nature allows for intricate designs and curves that are difficult to achieve with heavier materials. The variety of colors and finishes allows for personalization and customization, ensuring the building reflects the desired aesthetic. The material’s ability to withstand various weather conditions means the building maintains its attractive appearance for years to come, without requiring extensive maintenance. The overall effect is a visually striking and durable exterior that enhances the property’s curb appeal and market value.

Onduline Cladding

Source: onduline.com

Onduline cladding, while relatively low-maintenance, still requires periodic attention to ensure its longevity and aesthetic appeal. Regular checks and simple cleaning can prevent minor issues from becoming major repairs, saving you time and money in the long run. This section details the necessary maintenance procedures and repair methods for common problems.

Routine Maintenance Procedures

Regular inspection is key to maintaining your Onduline cladding. Ideally, conduct a visual inspection twice a year, in spring and autumn. Look for any signs of damage, such as cracks, punctures, or loose panels. Check the flashing around windows and doors for any gaps or deterioration. Also, inspect the fasteners to ensure they are secure. Addressing minor issues promptly prevents them from escalating into more significant problems. For example, a small crack ignored could lead to water ingress and subsequent damage to the underlying structure.

Repairing Damaged Onduline Cladding

Minor cracks can often be repaired using Onduline’s repair masticant. This sealant is specifically designed for Onduline products and provides a flexible, waterproof seal. Apply the masticant according to the manufacturer’s instructions, ensuring complete coverage of the crack. For punctures, a similar approach is used, but a small piece of Onduline sheet may need to be cut to fit over the hole before applying the mastic for added strength and protection. Larger areas of damage may require replacing the affected panels. This typically involves carefully removing the damaged panel, ensuring not to damage adjacent ones, and replacing it with a new one using appropriate fasteners.

Cleaning Onduline Cladding and Stain Removal

Cleaning Onduline cladding is generally straightforward. Regularly remove loose debris such as leaves and dirt using a soft brush or broom. For more stubborn dirt or stains, a mild detergent solution can be used. Apply the solution with a soft sponge or cloth, scrubbing gently to avoid damaging the surface. Rinse thoroughly with clean water afterward. Avoid using harsh chemicals or abrasive cleaners, as these can damage the Onduline surface. For persistent stains, consider using a pressure washer set to a low pressure setting, keeping a safe distance to prevent damage. Always test any cleaning solution on a small, inconspicuous area first to ensure it doesn’t affect the color or finish of the cladding.

Lifespan and Factors Affecting Longevity

The lifespan of Onduline cladding can vary depending on several factors. Under ideal conditions, it can last for many years, often exceeding 20 years. However, factors such as extreme weather conditions (intense sun, heavy snow, or strong winds), improper installation, and neglect can significantly reduce its lifespan. For instance, areas exposed to prolonged and intense sunlight might experience faster fading of the color. Similarly, poorly installed flashing around windows and doors can lead to water ingress and premature degradation. Regular maintenance, as described above, plays a crucial role in extending the lifespan of your Onduline cladding and ensuring its continued performance.

Onduline Cladding

Source: co uk

Onduline cladding offers a lightweight, durable, and aesthetically pleasing alternative to traditional cladding materials. Its ease of installation and low maintenance requirements make it a popular choice for a variety of projects, from residential renovations to commercial buildings. This section will delve into the cost and value proposition of Onduline cladding, comparing it to other options and highlighting its long-term benefits.

Onduline Cladding Cost Comparison

The initial cost of Onduline cladding, like any building material, depends on factors such as the project size, complexity, and regional variations in pricing. However, it generally falls within a competitive range compared to other cladding options. The following table provides a general comparison, keeping in mind that these figures are estimates and can vary significantly based on location and specific project requirements.

| Material | Material Cost per sq ft (USD) | Installation Cost per sq ft (USD) | Overall Cost per sq ft (USD) |

|---|---|---|---|

| Onduline Cladding | 2-4 | 3-5 | 5-9 |

| Wood Siding | 5-10 | 5-8 | 10-18 |

| Vinyl Siding | 3-6 | 4-6 | 7-12 |

| Metal Siding | 6-12 | 6-10 | 12-22 |

Onduline Cladding Project Examples

Several successful projects have leveraged the benefits of Onduline cladding. The choice of Onduline often stems from its unique combination of affordability, durability, and ease of installation.

Here are a few illustrative examples:

- A coastal cottage renovation in Maine: Onduline’s resistance to moisture and salt spray made it the ideal choice for protecting the building’s exterior. The lightweight nature of the material also simplified installation, minimizing disruption to the existing structure.

- A modern agricultural building in Iowa: The need for a cost-effective, weather-resistant cladding solution led to the selection of Onduline. Its durability and ease of installation proved beneficial in a rural setting.

- A commercial retail building in California: The architect chose Onduline for its aesthetic versatility and ability to create a unique design element. The ease of installation allowed for a faster project completion timeline.

Long-Term Value and Cost-Effectiveness of Onduline Cladding

The long-term value of Onduline cladding lies in its durability and low maintenance requirements. Unlike some cladding materials that require frequent repainting or repairs, Onduline offers exceptional longevity, minimizing ongoing expenses. Its resistance to rot, insect infestation, and extreme weather conditions contributes significantly to its cost-effectiveness over the building’s lifespan. The initial investment is often offset by reduced maintenance costs and extended lifespan compared to other materials.

Cost Savings from Easy Installation and Low Maintenance

The ease of installation of Onduline cladding translates directly into cost savings. Its lightweight nature and simple application process require less labor time and specialized equipment compared to other cladding systems. This reduction in labor costs significantly impacts the overall project budget. Furthermore, the low maintenance aspect eliminates the recurring expenses associated with repainting, repairs, and replacements, further enhancing the long-term cost-effectiveness of Onduline cladding. For example, a homeowner might save hundreds of dollars annually by avoiding the need for regular repainting, a common expense with traditional wood or metal siding.

Final Review

Source: onduline.com

From its lightweight yet durable nature to its diverse aesthetic applications, Onduline cladding presents a practical and visually appealing option for a range of building projects. By understanding its properties, installation methods, and maintenance requirements, you can confidently leverage its benefits to create a stunning and long-lasting exterior. Remember to always refer to the manufacturer’s guidelines for best results and to ensure a safe and successful installation. This comprehensive guide has equipped you with the knowledge to confidently incorporate Onduline cladding into your next project.