Seam Roof Panels A Comprehensive Guide

Seam roof panels represent a top-tier roofing solution, offering a blend of durability, aesthetics, and longevity. This guide delves into the world of seam roof panels, exploring various materials like steel, aluminum, and copper, each with unique profiles such as standing seam, batten seam, and rib seam. We’ll cover installation techniques, maintenance strategies, and even compare them to other roofing options. Get ready to become a seam roof panel expert!

From understanding the different types and their respective lifespans to mastering the installation process and addressing common maintenance issues, we’ll equip you with the knowledge to make informed decisions about your roofing project. We’ll also look at the pros and cons, ensuring you’re fully aware of what to expect. Whether you’re a homeowner, contractor, or simply curious, this guide provides a comprehensive overview of seam roof panels.

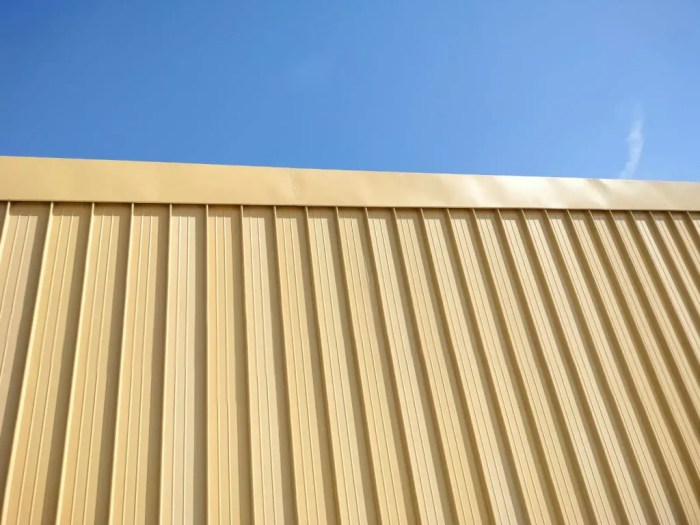

Types of Seam Roof Panels

Source: kindus.com

Seam roof panels offer a durable and aesthetically pleasing roofing solution for various building types. Choosing the right panel depends on factors like budget, desired lifespan, and the building’s architectural style. Understanding the different materials and profiles available is crucial for making an informed decision.

Seam Roof Panel Materials

Several materials are commonly used in the manufacturing of seam roof panels, each offering a unique set of properties. Steel, aluminum, and copper are the most prevalent choices. Steel panels are generally the most cost-effective option, offering good strength and durability. Aluminum panels are lighter than steel, providing superior corrosion resistance, making them ideal for coastal areas or environments with high humidity. Copper panels are the most expensive but boast exceptional longevity and a distinctive, naturally developing patina that enhances their aesthetic appeal over time. Zinc is another option, offering similar longevity to copper but with a different aesthetic.

Seam Roof Panel Profiles

The profile of a seam roof panel significantly impacts its appearance and performance. Standing seam panels feature a high profile with vertical seams, creating a sleek and modern look. Batten seam panels have a more traditional appearance, with visible seams that resemble batten boards. Rib seam panels offer a more textured surface, with raised ribs running parallel to the seams. The choice of profile is largely a matter of aesthetic preference, though certain profiles may be better suited to specific climates or building designs. For example, standing seam panels are excellent at shedding snow.

Lifespan and Maintenance of Seam Roof Panels

The lifespan and maintenance requirements of seam roof panels vary considerably depending on the chosen material. Steel panels, while durable, may require periodic repainting to maintain their protective coating and prevent rust. Aluminum panels are virtually maintenance-free, requiring minimal upkeep beyond occasional cleaning. Copper panels develop a protective patina that requires no maintenance and increases their longevity. However, the initial cost of copper is significantly higher. The lifespan of steel panels typically ranges from 20-50 years, aluminum panels from 40-70 years, and copper panels from 50-100 years or more, depending on environmental factors and installation quality.

Comparison of Seam Roof Panel Types

| Panel Type | Cost | Durability | Aesthetic Appeal |

|---|---|---|---|

| Steel | Low | Medium (20-50 years) | Versatile, various colors available |

| Aluminum | Medium | High (40-70 years) | Modern, sleek appearance |

| Copper | High | Very High (50-100+ years) | Classic, develops a unique patina |

| Zinc | Medium-High | Very High (50-100+ years) | Modern, develops a silvery-grey patina |

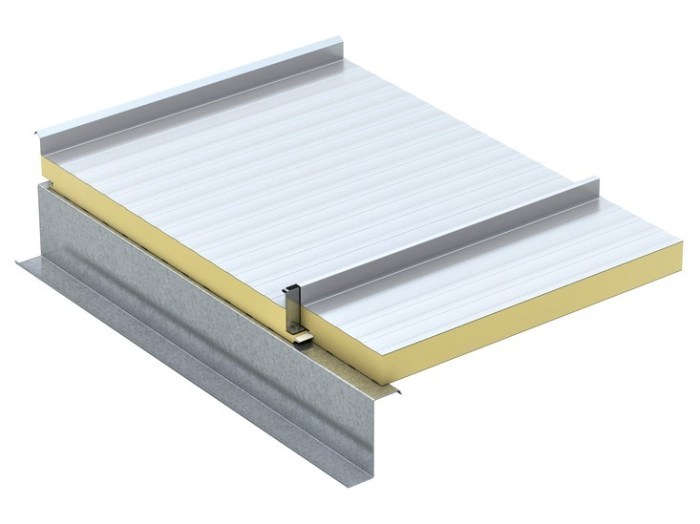

Seam Roof Panel Installation

Source: spaceframe.ae

Installing seam roof panels requires careful planning and execution to ensure a durable and watertight roof. This process involves several key steps, from proper preparation to final sealing, and demands the use of specialized tools and techniques. Following best practices is crucial for a long-lasting and leak-free roof.

Tools and Equipment

A successful seam roof panel installation relies on having the right tools. Improper tools can lead to damage to the panels, inaccurate installation, and ultimately, leaks. The following list includes Articles’ essential equipment:

- Measuring tape: Accurate measurements are fundamental for precise panel cutting and placement.

- Metal shears or circular saw with a metal-cutting blade: Necessary for cutting panels to size. A circular saw offers speed for large projects, but shears provide more control for intricate cuts.

- Drill with appropriate drill bits: Used for pilot holes when fastening panels.

- Screwdriver or impact driver: For securing the panels with appropriate fasteners.

- Level: Ensures panels are installed correctly, preventing water pooling.

- Seam sealer and applicator: Creating a watertight seal between panels is paramount; appropriate sealants are essential.

- Safety equipment: This includes safety glasses, gloves, and fall protection equipment. Roofing is inherently dangerous work.

- Snap-lock pliers or seam crimper (depending on panel type): These tools help form a tight, weatherproof seal at panel seams.

- Chalk line: For marking straight lines on the roof deck, aiding accurate panel placement.

Preparation

Thorough preparation is vital for a smooth and efficient installation. This includes ensuring the roof deck is properly prepared to receive the panels. Any existing damage or debris needs to be addressed before installation begins.

- Inspect and clean the roof deck: Remove any debris, loose materials, or existing roofing elements.

- Ensure the roof deck is structurally sound: Repair any damaged areas before starting the installation.

- Check for proper slope and drainage: Adequate slope is essential for water runoff; correct any issues that might impede drainage.

- Measure and mark the roof: Accurate measurements are crucial for cutting panels to the correct size and layout.

Panel Fastening and Seaming

Fastening and seaming the panels correctly is crucial for both structural integrity and waterproofing. Using the correct fasteners and sealing techniques is vital.

- Begin installation at the lowest point of the roof: This allows for proper overlapping and water runoff.

- Secure panels using appropriate fasteners: Follow manufacturer’s recommendations for fastener type, spacing, and placement. Over-tightening can damage panels.

- Crimp or snap-lock seams: Use the appropriate tools to ensure a tight and weatherproof seal between panels.

- Apply seam sealant: After crimping or snap-locking, apply a bead of high-quality seam sealant along all seams to further enhance waterproofing.

Best Practices for Watertight Seals

Achieving a watertight seal is the ultimate goal. This requires meticulous attention to detail throughout the installation process.

- Use high-quality seam sealant: Choose a sealant specifically designed for metal roofing and suitable for the climate.

- Ensure complete coverage of all seams: Leave no gaps or unsealed areas.

- Apply sealant evenly: Avoid excessive buildup or thin applications.

- Inspect all seams after installation: Check for any gaps or imperfections and address them immediately.

Step-by-Step Visual Guide

- Image 1: Roof Deck Preparation – This image shows a clean and structurally sound roof deck, ready for panel installation. All debris has been removed, and any necessary repairs have been completed. The roof deck is visible, showing its even surface and proper slope.

- Image 2: Panel Measurement and Cutting – This image displays accurate measurement using a tape measure and the careful cutting of a panel using metal shears. The cut is clean and precise, ensuring a perfect fit.

- Image 3: Panel Placement and Fastening – This image shows a worker carefully placing a panel onto the roof deck, ensuring proper alignment and overlap. Fasteners are being installed using a drill and impact driver, following manufacturer specifications for spacing.

- Image 4: Seam Crimping/Snap-Locking – This image illustrates the use of snap-lock pliers or a seam crimper to create a tight, weatherproof seal between two adjacent panels. The tool is correctly positioned, and the seam is being firmly joined.

- Image 5: Sealant Application – This image shows the application of seam sealant along the crimped/snap-locked seam. A consistent bead of sealant is applied, ensuring complete coverage and a watertight seal.

- Image 6: Completed Installation – This image showcases the completed roof, with all panels installed and seams sealed. The roof appears neat, even, and ready to withstand the elements.

Advantages and Disadvantages of Seam Roof Panels

Source: kindus.com

Choosing the right roofing material is a big decision, impacting both the aesthetics and longevity of your building. Seam roof panels represent a strong contender in the roofing market, offering a unique blend of benefits and drawbacks. Understanding these aspects is crucial for making an informed choice. This section will delve into the pros and cons of seam roof panels, comparing them to other common roofing options.

Durability and Longevity of Seam Roof Panels

Seam roof panels are renowned for their exceptional durability. The interlocking seams create a highly watertight system, resistant to leaks and weathering. High-quality panels, often made from steel or aluminum, can withstand significant wind loads and heavy snowfall. This inherent strength translates to a remarkably long lifespan, often exceeding 50 years with proper maintenance. This longevity reduces the frequency of costly roof replacements, offering significant long-term savings. For example, a properly installed seam metal roof on a commercial building in a high-wind area could easily last twice as long as a comparable asphalt shingle roof, significantly reducing replacement costs over the building’s lifespan.

Energy Efficiency Aspects of Seam Roof Panels

Seamless metal roofs are surprisingly energy-efficient. Their reflective surfaces minimize heat absorption, reducing the amount of energy needed to cool the building during hot summer months. This energy saving can be substantial, leading to lower energy bills and a smaller carbon footprint. The reflective properties are particularly advantageous in areas with intense sunlight. For instance, a building with a light-colored seam metal roof in a desert climate might experience a significant reduction in cooling costs compared to a dark-colored asphalt shingle roof. Additionally, proper insulation beneath the panels further enhances energy efficiency.

Cost Analysis of Seam Roof Panels Compared to Other Materials

While the initial cost of seam roof panels is generally higher than that of asphalt shingles or tiles, the long-term value proposition is compelling. The extended lifespan and reduced maintenance needs offset the higher upfront investment over time. Comparing a 50-year lifespan for a seam metal roof to a 20-year lifespan for asphalt shingles reveals the significant cost savings in the long run, even accounting for the higher initial purchase price. The total cost of ownership, considering both initial investment and future replacements, often makes seam panels a more cost-effective solution in the long term.

Potential Drawbacks of Seam Roof Panels

Despite their many advantages, seam roof panels are not without their drawbacks. One significant factor is the higher initial cost compared to other roofing materials. Installation can also be more complex and require specialized expertise, potentially leading to higher labor costs. Furthermore, while durable, seam panels can be susceptible to damage from hail or extreme weather events. Dents or scratches, though usually superficial, can compromise the aesthetic appeal and, in severe cases, lead to leaks if not promptly addressed.

Comparison of Seam Roof Panels with Other Roofing Materials

- Cost: Seam roof panels typically have a higher initial cost than asphalt shingles or clay tiles but offer significant long-term savings due to their extended lifespan and reduced maintenance.

- Longevity: Seam roof panels significantly outlast asphalt shingles and clay tiles, often lasting 50 years or more compared to 20-30 years for other materials.

- Maintenance: Seam roof panels require minimal maintenance compared to other roofing materials, which may need regular cleaning, repairs, or replacements.

- Energy Efficiency: Seam roof panels, especially light-colored ones, offer superior energy efficiency compared to darker roofing materials by reflecting sunlight and reducing heat absorption.

- Durability: While generally durable, seam roof panels can be susceptible to damage from extreme weather events such as hail, unlike some other materials, which are more resistant to minor impacts.

Seam Roof Panel Maintenance and Repair

Source: kindus.com

Proper maintenance is key to extending the lifespan of your seam roof panels and preventing costly repairs down the line. Neglecting regular upkeep can lead to premature wear, leaks, and structural damage. Thissection articulatess common issues, cleaning procedures, minor repair techniques, and when to call in a professional.

Common Seam Roof Panel Issues

Several factors contribute to problems with seam roof panels. These include exposure to harsh weather conditions (extreme temperatures, heavy snow, hail, and strong winds), improper installation, and general wear and tear. Common issues include dents, scratches, rust, sealant failure at seams, and panel punctures. These problems can compromise the roof’s integrity, leading to leaks and potential structural damage if left unaddressed.

Cleaning and Maintaining Seam Roof Panels

Regular cleaning helps prevent many issues. Start by removing loose debris like leaves, twigs, and dirt with a soft-bristled broom. For tougher stains, use a solution of mild detergent and water, applying it with a soft sponge or brush. Rinse thoroughly with clean water afterward, ensuring all soap residue is removed to avoid staining or attracting more dirt. Avoid harsh chemicals or high-pressure washers, as these can damage the panel’s finish or sealant. Annual cleaning, particularly in areas with heavy debris accumulation, is recommended. Regular inspection for loose fasteners, damaged seals, or signs of rust is also crucial.

Repairing Minor Damage to Seam Roof Panels

Minor dents and scratches can often be repaired without professional help. Small dents can sometimes be carefully pushed back into shape using a rubber mallet and a wooden block to avoid further damage. For scratches that penetrate the paint, clean the area thoroughly and apply a touch-up paint designed for metal roofing. Ensure the paint is compatible with the original panel finish. If the sealant at a seam has failed, carefully remove any loose or damaged sealant, clean the area, and apply a high-quality, weatherproof sealant designed for metal roofing. Follow the manufacturer’s instructions for application and curing time. Always allow sufficient drying time before exposing the repaired area to rain or snow.

Identifying Problems Requiring Professional Attention

While minor repairs can be handled DIY, certain issues require the expertise of a professional roofing contractor. These include significant dents or punctures that compromise the panel’s structural integrity, widespread rust, large areas of sealant failure, and leaks. If you notice any signs of water damage inside the building, such as water stains on ceilings or walls, or if you observe significant corrosion or damage to the supporting structure, professional assessment is essential. Ignoring major issues can lead to extensive and costly repairs or even complete roof replacement. A professional can diagnose the problem accurately, recommend the best course of action, and ensure the repairs are done correctly, preserving the roof’s longevity and preventing further damage.

Seam Roof Panel Applications and Design Considerations

Source: roof-experts.ca

Seam roof panels offer a versatile and durable roofing solution suitable for a wide range of building types and architectural styles. Their clean lines and customizable features make them a popular choice for both modern and traditional designs, enhancing both functionality and aesthetics. Understanding the appropriate applications and design considerations is crucial for successful project implementation.

Suitable Applications for Seam Roof Panels

Seam roof panels are exceptionally well-suited for various building applications. Their strength, weather resistance, and longevity make them ideal for diverse projects. Industrial buildings, for instance, benefit from the panels’ ability to withstand heavy loads and harsh weather conditions. Commercial structures can leverage their aesthetic appeal and energy efficiency. Residential applications demonstrate their adaptability to varying roof designs and architectural styles.

- Industrial Buildings: Warehouses, factories, and manufacturing plants often utilize seam roof panels due to their robust nature and ability to span large distances, minimizing the need for internal supports. The panels’ resistance to impact and corrosion is particularly advantageous in these environments.

- Commercial Buildings: Office buildings, retail spaces, and shopping centers can incorporate seamless roof panels to create a sleek and modern aesthetic. Their energy efficiency contributes to reduced operational costs, while their durability ensures long-term performance.

- Residential Buildings: From barns and garages to modern homes, seamless roof panels offer a stylish and practical roofing solution. Their variety of colors and finishes allows for customization to complement different architectural styles and personal preferences. The relatively easy installation compared to other roofing materials is also beneficial.

Design Considerations for Different Architectural Styles

Choosing the right seam roof panel profile and material is crucial for achieving a cohesive design. The architectural style dictates the appropriate panel selection, ensuring both functionality and aesthetic integration. For instance, a contemporary building might utilize a standing seam panel for its clean, minimalist look, while a more traditional structure could employ a ribbed panel to achieve a classic appearance. Color and finish selection are also essential considerations, ensuring harmony with the overall building design.

- Modern Architecture: Standing seam panels in sleek metallic finishes (e.g., aluminum or zinc) are often preferred for their clean lines and contemporary aesthetic. The panels’ ability to create expansive, uninterrupted roof planes further enhances the modern look.

- Traditional Architecture: Ribbed or corrugated seam panels can be used to mimic the appearance of traditional roofing materials, while still providing the benefits of modern metal roofing. Darker colors and textured finishes can help integrate the panels into a more classic design.

- Rustic Architecture: Seam panels with a weathered or aged finish can create a rustic look that complements buildings with natural wood or stone elements. Earth tones and textured finishes help to blend the roofing seamlessly with the overall architectural style.

Examples of Innovative and Aesthetically Pleasing Applications, Seam roof panels

Innovative applications of seam roof panels showcase their adaptability and design potential. Buildings can incorporate unique panel profiles, colors, and finishes to create visually striking results. Curved roof designs, for instance, demonstrate the panels’ flexibility and ability to conform to complex geometries. The use of contrasting colors or metallic finishes can add visual interest and enhance the overall aesthetic.

Imagine a modern office building with a gently sloping roof covered in charcoal-grey standing seam panels. The clean lines of the panels contrast beautifully with the building’s glass facade, creating a sleek and sophisticated look. The panels’ reflective properties also help to reduce energy consumption.

Alternatively, picture a rustic barn with a steeply pitched roof covered in dark brown ribbed seam panels. The panels’ texture and color complement the building’s wooden siding and stone foundation, creating a harmonious and inviting aesthetic. The panels’ durability ensures the roof will withstand the elements for years to come.

Visual Representation of Seam Roof Panel Applications

Imagine a collage showcasing various applications. The first image shows a sprawling industrial warehouse with a vast expanse of long, straight standing seam panels in a muted grey, emphasizing strength and functionality. Next, a sleek, multi-story office building with a contemporary design boasts a slightly curved roof covered in gleaming silver panels, showcasing a modern and elegant aesthetic. A third image depicts a charming residential home with a steep, gabled roof adorned with deep red ribbed panels, evoking a sense of warmth and traditional charm. Finally, a picture of a large, open-air pavilion utilizes a series of intersecting, color-coordinated panels to create a visually stunning and functional structure. Each image highlights the versatility of seam roof panels across different building types and architectural styles, demonstrating their ability to enhance both functionality and aesthetics.

Last Word

Source: azureedge.net

Ultimately, choosing seam roof panels involves balancing cost, aesthetics, and long-term performance. While the initial investment might be higher than some alternatives, the durability and longevity of seam roof panels often translate to significant long-term savings and reduced maintenance headaches. By understanding the various types, installation processes, and maintenance requirements, you can confidently select the perfect seam roof panel system to meet your specific needs and create a truly lasting roof.