Facade Retention Systems Safeguarding Building Faces

Facade retention systems are crucial for modern construction, allowing for the safe and efficient reuse of existing building facades during renovations or expansions. These systems support and secure the exterior walls, enabling intricate designs and minimizing disruption. We’ll explore the various types, components, design considerations, and best practices for installation and maintenance, ensuring a thorough understanding of this essential building technology.

From the engineering principles that underpin their design to the diverse materials employed—steel, aluminum, composites, and more—we’ll delve into the specifics of facade retention systems. We’ll also examine successful case studies, highlighting both the challenges and triumphs of their implementation in diverse building types and climates.

Introduction to Facade Retention Systems

Source: alamy.com

Facade retention systems are crucial in modern construction, allowing for the preservation of existing building facades during renovations or extensions. This process involves carefully removing and supporting the facade, allowing for the construction of a new structure behind it, before finally reintegrating the original facade. This approach offers significant aesthetic and historical advantages, maintaining the character of a building while upgrading its functionality and structural integrity. It’s a sophisticated technique requiring careful planning and execution.

Facade retention systems offer several benefits. Firstly, they preserve the architectural heritage of a building, maintaining its unique aesthetic appeal and contributing to the character of the surrounding area. Secondly, they can be more cost-effective than complete demolition and reconstruction, saving both time and resources. Finally, the retention of the facade can minimize disruption to the surrounding environment, reducing noise and dust pollution during the construction phase.

Types of Facade Retention Systems

The choice of facade retention system depends on various factors, including the type of facade material, its structural condition, and the overall design of the project. Several common systems are employed. These systems often involve a combination of techniques to ensure the stability and longevity of the retained facade.

- Steel Frame Systems: These systems utilize a robust steel framework to support the facade, transferring the load to the new building structure. The steel frame is carefully designed to accommodate the weight and dimensions of the facade, ensuring its stability and preventing damage.

- Masonry Support Systems: For brick or stone facades, masonry support systems might involve underpinning the existing foundations or installing temporary supports to maintain the integrity of the facade during construction. This often requires specialized expertise in masonry work and structural engineering.

- Suspended Facade Systems: In some cases, the facade is suspended from the new structure using a series of anchors and supports. This is particularly suitable for lightweight facades or where the existing structure is unsuitable for direct support.

- Combination Systems: Often, a combination of these systems is employed to provide the most effective and reliable support for the retained facade, tailoring the approach to the specific challenges presented by the building and its facade.

Examples of Facade Retention Projects

Numerous buildings worldwide showcase the successful implementation of facade retention systems. These projects demonstrate the versatility and effectiveness of these systems in various contexts.

- The renovation of historic warehouses in London: Many older warehouse buildings in London have undergone renovations that retained their original brick facades. Steel frame systems were frequently used to support the facades while the interior structures were modernized and updated to meet contemporary standards.

- Modern office building extensions in New York City: In several cases, modern office building extensions in New York City have incorporated facade retention systems to maintain the existing aesthetic of older buildings. These projects often involved intricate engineering solutions to integrate the old and new structures seamlessly.

- Residential building conversions in Paris: The renovation of older residential buildings in Paris often includes the retention of the building’s original facade. This allows for the preservation of the city’s architectural heritage while improving the functionality and energy efficiency of the buildings. Often, these projects utilize masonry support systems and careful restoration techniques.

Components of Facade Retention Systems

Source: prime-habitat.com

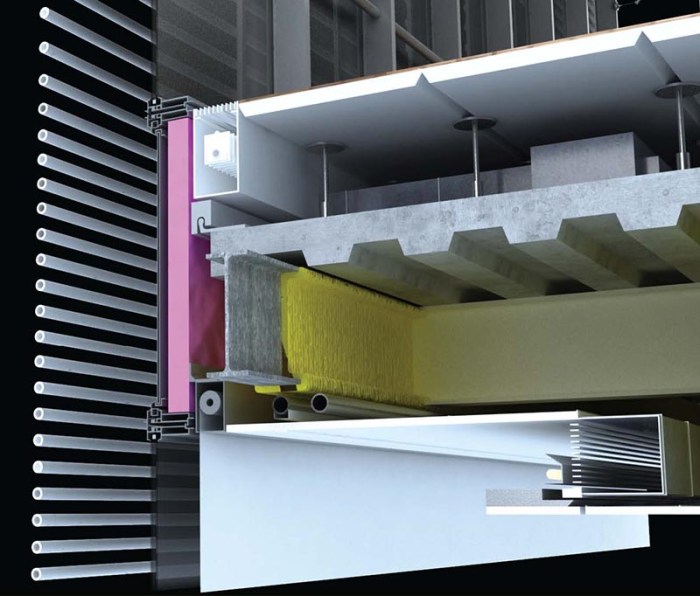

Facade retention systems are complex assemblies requiring careful consideration of numerous interacting components. Understanding these components is crucial for ensuring the system’s structural integrity, longevity, and aesthetic appeal. A well-designed system balances strength, flexibility, and ease of installation.

The key components work together in a coordinated manner to support the retained facade, transferring loads safely to the underlying structure. Failure in any one component can compromise the entire system, leading to potential damage or even collapse. Therefore, selecting appropriate materials and ensuring proper installation is paramount.

Key Components of Facade Retention Systems

A typical facade retention system includes several essential components: anchors, support structures (often including beams and columns), connection methods (to join these components), and the facade panels themselves. The specific components and their design will vary depending on the type of facade being retained, the building’s structural characteristics, and the overall design intent. Sometimes, additional components like bracing or wind load mitigation systems may be necessary.

Materials Used in Facade Retention Systems

The choice of materials significantly impacts the system’s performance, cost, and aesthetic properties. Different materials offer varying levels of strength, durability, weight, and cost-effectiveness.

| Material | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|

| Steel | High strength, excellent durability, versatile design options | Susceptible to corrosion, can be relatively heavy | High-rise buildings, complex facades |

| Aluminum | Lightweight, corrosion-resistant, relatively inexpensive | Lower strength compared to steel may require more extensive bracing | Mid-rise buildings, simpler facades |

| Composite Materials (e.g., fiberglass reinforced polymer) | High strength-to-weight ratio, corrosion resistance, design flexibility | It can be more expensive than steel or aluminum, with potential for long-term degradation | Specific applications requiring high strength and low weight |

Anchors, Supports, and Connection Methods

Anchors are crucial for securely attaching the retention system to the existing building structure. These anchors transfer the loads from the retained facade to the building’s structural elements. The type of anchor used depends on the building material (concrete, masonry, steel) and the loads being transferred. Common anchor types include expansion anchors, adhesive anchors, and headed studs.

Support structures, typically composed of steel or aluminum beams and columns, provide the framework for the retained facade. These structures distribute the loads from the anchors to the building’s foundation. The design of the support structure considers factors such as the weight of the facade, wind loads, and seismic activity. Careful consideration is given to minimizing deflection and ensuring stability.

Connection methods are essential for joining the various components of the retention system. These connections must be strong enough to withstand the loads and maintain the integrity of the system. Welding, bolting, and specialized connectors are commonly used, with the choice depending on the materials used and the design requirements. Proper detailing of these connections is critical to prevent premature failure.

Design and Engineering Considerations: Facade Retention Systems

Source: heightsafety.net

Designing and engineering facade retention systems requires a thorough understanding of structural mechanics, material science, and environmental factors. These systems must not only support the weight of the retained facade but also withstand various external loads, including wind, seismic activity, and thermal expansion. Careful consideration of these factors is crucial to ensure the safety and longevity of the building.

The engineering principles underpinning facade retention systems are based on ensuring stability and preventing failure under various load conditions. This involves calculating the loads acting on the system, selecting appropriate materials with sufficient strength and durability, and designing a robust connection between the retained facade and the supporting structure. Furthermore, the design must account for potential movement and deformation of the building structure itself, preventing stress concentrations and ensuring the system’s integrity.

Load Calculations and Material Selection

Accurate load calculations are paramount. These calculations must consider dead loads (the weight of the facade itself), live loads (occupancy loads, snow loads, etc.), and environmental loads (wind, seismic forces, thermal expansion). Software simulations are commonly employed to model the system’s behavior under different load combinations. Material selection depends on the specific loads and environmental conditions. High-strength steel, aluminum alloys, and composite materials are frequently used, chosen based on their strength-to-weight ratio, corrosion resistance, and fire performance. For example, a high-rise building in a hurricane-prone area might necessitate stronger materials and more robust connections compared to a low-rise building in a less exposed location.

Connection Design and Detailing

The design of connections between the retained facade and the supporting structure is critical. These connections must be strong enough to transfer loads effectively while allowing for some movement due to thermal expansion and building settlement. Proper detailing is essential to prevent corrosion and ensure long-term durability. Common connection types include bolted connections, welded connections, and adhesive bonding. The selection of the connection type depends on factors such as the type of material used, the magnitude of the loads, and the required level of flexibility. A poorly designed connection can lead to premature failure of the entire system.

Challenges and Limitations

Designing facade retention systems can present several challenges. One significant challenge is accommodating the movement of the building structure. Buildings settle and expand and contract due to thermal changes, and the retention system must be designed to accommodate these movements without causing stress concentrations or damage to the facade. Another challenge involves integrating the retention system with other building systems, such as HVAC and plumbing. Careful coordination is needed to ensure that the retention system does not interfere with the operation of these other systems. Finally, the complexity of the design and the need for specialized expertise can increase the cost and time required for the project. For instance, complex geometries or unusual materials might require extensive testing and analysis, potentially delaying construction.

Installation and Maintenance Procedures

Source: alamy.com

Proper installation and regular maintenance are crucial for the longevity and effectiveness of any facade retention system. Neglecting these aspects can lead to premature system failure, compromising building safety and aesthetics. This section details the typical installation process for a common system and Artikels best practices for maintenance and inspection.

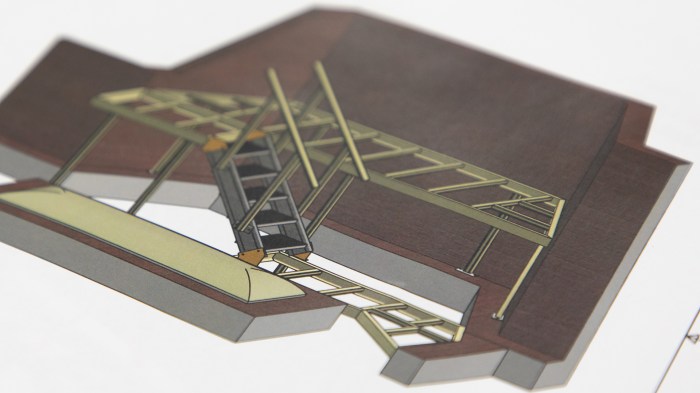

Step-by-Step Installation of a Typical Curtain Wall System

The following steps Artikel the installation of a typical curtain wall system, a common type of facade retention system. Variations will exist depending on the specific system and building design, but these steps provide a general overview. Always refer to the manufacturer’s specific instructions.

- Substructure Preparation: Ensure the building’s structural frame is properly prepared to receive the curtain wall system. This includes verifying the accuracy of the framing, ensuring adequate anchoring points, and cleaning the surfaces. Any deviations from the design specifications must be addressed before proceeding.

- Framing Installation: Install the primary support framework, typically made of aluminum or steel, according to the design drawings. Precise measurements and leveling are critical at this stage to ensure the overall alignment of the facade.

- Panel Installation: Attach the individual curtain wall panels to the framework. This usually involves securing the panels with fasteners and applying sealant to ensure weather tightness. Careful handling of the panels is essential to prevent damage.

- Glazing Installation: Insert and secure the glass units into the panels. This step requires specialized tools and techniques to ensure proper installation and prevent breakage. The use of proper spacers and sealants is crucial for energy efficiency and weather resistance.

- Flashing and Sealant Application: Apply flashing and sealant around all joints and penetrations to create a watertight barrier. This prevents water infiltration, which can lead to damage to the building’s structure and interior finishes.

- Final Inspection: Conduct a thorough inspection of the entire system to verify proper installation and address any deficiencies. This may involve checking for alignment, water tightness, and structural integrity.

Maintenance and Inspection Best Practices

Regular inspection and maintenance are essential to prolong the life and performance of a facade retention system. A proactive approach can prevent costly repairs and ensure building safety.

- Regular Inspections: Conduct visual inspections at least twice a year, focusing on areas prone to damage, such as joints, seals, and fasteners. More frequent inspections may be necessary in harsh climates or areas with high pollution.

- Cleaning: Clean the facade regularly to remove dirt, debris, and pollutants that can accelerate deterioration. Use appropriate cleaning methods to avoid damaging the system’s components.

- Sealant Inspection and Replacement: Inspect the sealant regularly for cracks, gaps, or deterioration. Replace damaged sealant promptly to maintain the system’s water tightness.

- Fastener Inspection and Tightening: Check all fasteners for looseness or corrosion. Tighten loose fasteners and replace corroded ones to ensure structural integrity.

- Documentation: Maintain detailed records of all inspections and maintenance activities. This information is valuable for tracking the system’s condition and planning future maintenance.

Common Installation and Maintenance Issues and Solutions, Facade retention systems

Several issues can arise during the installation and maintenance of facade retention systems. Addressing these promptly can prevent significant problems.

- Improper Alignment: Misalignment during installation can lead to stress on the system and potential failure. Solutions include careful measurement and leveling during installation and correction of any misalignment as soon as it’s detected.

- Water Infiltration: Leaks can cause significant damage to the building’s interior. Solutions involve identifying the source of the leak (often faulty sealant or damaged panels), repairing the damaged components, and applying new sealant.

- Corrosion: Corrosion of metal components can weaken the system and compromise its structural integrity. Solutions include using corrosion-resistant materials, applying protective coatings, and replacing corroded components.

- Sealant Failure: Deterioration of sealant can lead to water infiltration and other problems. Solutions involve regular inspection and prompt replacement of damaged sealant.

- Panel Damage: Damage to panels can occur during installation or due to external factors. Solutions include replacing damaged panels and taking steps to prevent future damage.

Safety Regulations and Standards

Source: co uk

Facade retention systems, due to their inherent role in building safety and structural integrity, are subject to a rigorous set of safety regulations and standards. These regulations vary depending on location and the specific type of system used, but all aim to minimize risks to workers during installation and maintenance, and to ensure the long-term safety of the building occupants. Compliance is paramount for both legal reasons and to ensure public safety.

Adherence to these standards is crucial for preventing accidents and ensuring the structural integrity of the building. Failure to comply can lead to serious consequences, including fines, project delays, and potential liability for injuries or damage. The design, installation, and maintenance of facade retention systems must be meticulously documented to demonstrate compliance with all applicable regulations.

Relevant Safety Regulations and Building Codes

Building codes and safety regulations governing facade retention systems are typically found within broader construction codes, often incorporating specific clauses addressing high-rise buildings and external facade elements. These codes usually address aspects like load bearing capacity, wind resistance, impact resistance, fire safety, and fall protection during installation and maintenance. For example, OSHA (Occupational Safety and Health Administration) in the United States has specific regulations concerning fall protection for workers involved in high-rise construction, directly impacting the installation of facade retention systems. Similarly, the UK’s Construction (Design and Management) Regulations 2015 (CDM 2015) place responsibilities on designers and contractors to manage health and safety risks associated with facade works. These regulations often necessitate detailed risk assessments and method statements for all phases of the project. Specific requirements vary based on the jurisdiction and the complexity of the project.

Comparison of International Standards

Several international standards guide the design, installation, and testing of facade retention systems. While not universally adopted, these standards offer a framework for best practices. For example, EN 1991-1-4 (Eurocode 1: Actions on structures – Part 1-4: Wind actions) guides wind loading calculations crucial for the design of facade retention systems, particularly in exposed locations. Similarly, standards like ASTM (American Society for Testing and Materials) standards offer testing procedures for material properties and system performance under various loading conditions. While these standards may differ in specific requirements, the underlying principle remains consistent: to ensure the safety and longevity of the facade system. Differences may lie in the specific test methods used, the allowable stress levels, and the level of detail required in documentation.

Incorporation of Safety Standards into Design and Installation

Safety standards are integrated into the design and installation processes through several key mechanisms. Firstly, detailed risk assessments are conducted during the design phase to identify potential hazards associated with the system’s installation and maintenance. These assessments inform the design choices, leading to the selection of appropriate materials, components, and installation methods. For instance, the use of fall arrest systems during installation is a direct consequence of addressing fall hazards identified in the risk assessment. Secondly, design calculations ensure the system meets or exceeds the required load-bearing capacity, wind resistance, and other performance criteria stipulated by relevant building codes and standards. Detailed engineering drawings and specifications Artikel the system’s design, materials, and installation procedures. Thirdly, rigorous quality control measures are implemented during the installation phase to ensure compliance with the design specifications and safety regulations. This includes regular inspections, material testing, and adherence to safe working practices. Finally, comprehensive documentation is maintained throughout the entire process, providing a record of compliance with safety standards and regulations. This documentation often includes detailed design calculations, risk assessments, inspection reports, and maintenance logs.

Case Studies

Source: smartcapitalmind.com

Successful facade retention system projects demonstrate the effectiveness and versatility of this approach to building renovation and refurbishment. These projects highlight the ability to preserve historical character while improving energy efficiency and structural integrity. Examining these case studies provides valuable insights into the challenges encountered and the solutions implemented.

Case Study: The Revitalization of the Old Town Hall

This project involved the retention of a historic building’s facade during a major internal renovation. The Old Town Hall, built in 1880, presented several challenges. The existing brick facade, while aesthetically pleasing, was structurally unsound in several areas due to age and weathering. Furthermore, the building’s internal layout needed significant updating to meet modern accessibility standards. The solution involved a carefully planned facade retention system using a combination of steel supports and high-strength epoxy resins to stabilize the weakened brickwork. New insulation was added behind the retained facade to significantly improve energy efficiency. The project successfully preserved the historical character of the building while enhancing its functionality and longevity. The retained facade became a focal point of the revitalized town square, attracting both residents and tourists. The project’s success was attributed to meticulous planning, precise engineering, and skilled craftsmanship.

Comparison of Facade Retention System Projects

The following table compares three different projects, showcasing the diversity of applications and outcomes for facade retention systems.

| System Type | Building Type | Project Outcomes | Climate |

|---|---|---|---|

| Steel Frame with Brick Anchoring | Commercial Office Building (1960s) | Improved energy efficiency, extended building lifespan, reduced maintenance costs. | Temperate, with moderate rainfall and snowfall. |

| Reinforced Concrete Frame with Cladding Retention | Residential Apartment Building (1920s) | Enhanced aesthetic appeal, improved structural integrity, updated building services. | Subtropical, with high humidity and occasional extreme weather events. |

| Aluminum Frame with Curtain Wall Integration | Modern Retail Space (2010s) | Enhanced visual appeal, improved thermal performance, and facilitated the incorporation of new technologies. | Arid, with significant temperature fluctuations. |

Long-Term Performance and Durability

The long-term performance of facade retention systems is heavily influenced by the chosen materials, the design’s robustness, and the prevailing climate. Systems employing durable materials such as stainless steel or high-strength concrete tend to exhibit greater longevity. Proper design considerations, including adequate drainage and protection against water ingress, are crucial for preventing premature deterioration. In climates with harsh winters, systems need to be designed to withstand freeze-thaw cycles and potential ice buildup. In coastal regions, resistance to salt spray is paramount. Regular maintenance, including cleaning and inspection, is essential for ensuring the long-term performance and aesthetic appeal of the system. For example, a facade retention system in a humid tropical climate may require more frequent cleaning and potential treatment to prevent the growth of mold and mildew compared to a system in a desert climate. Proper material selection, such as using corrosion-resistant materials in coastal areas or freeze-thaw resistant materials in colder climates, is crucial for ensuring longevity.

Cost-Effectiveness and Sustainability

Source: alamy.com

Facade retention systems offer a compelling blend of cost-effectiveness and sustainability, making them an attractive option for many construction projects. While the initial investment might seem higher compared to complete demolition, the long-term benefits often outweigh the upfront costs, leading to significant savings and reduced environmental impact. This section will explore these aspects in detail.

Choosing a facade retention system can lead to considerable cost savings compared to full demolition and rebuilding. The primary cost savings come from avoiding the expenses associated with complete material removal, disposal, and new material acquisition. Demolition and waste disposal can be surprisingly expensive, and the cost of new materials, especially in times of fluctuating market prices, can significantly impact a project’s budget. Retaining existing facades also often reduces the project timeline, further contributing to cost savings by minimizing labor costs and project financing burdens. For example, a project in London using facade retention saved an estimated 15% on overall construction costs compared to a similar project that opted for complete demolition.

Cost Comparison with Alternative Methods

A detailed cost comparison should consider various factors, including the condition of the existing facade, the complexity of the retention system required, labor costs, and the cost of new materials. A comprehensive analysis would involve obtaining quotes from contractors specializing in both facade retention and complete demolition. This comparison should include a breakdown of the costs for each stage of the project, including design, engineering, material acquisition, installation, and any necessary repairs or restoration of the retained facade. The total cost for each approach can then be compared, along with a detailed analysis of potential cost overruns or unexpected expenses. Often, a life-cycle cost analysis, considering maintenance and repair costs over the building’s lifespan, will highlight the long-term economic advantages of facade retention.

Sustainable Materials and Practices

Integrating sustainable materials and practices into facade retention systems is crucial for minimizing environmental impact. This can involve selecting recycled or reclaimed materials for components like structural supports or insulation. The use of locally sourced materials reduces transportation emissions, and selecting materials with high recycled content minimizes the demand for virgin resources. Furthermore, employing sustainable construction techniques, such as minimizing waste generation during installation and using energy-efficient materials, can further enhance the system’s sustainability profile. For example, incorporating green roofs or vertical gardens onto the retained facade can improve insulation, reduce the urban heat island effect, and provide habitat for local wildlife.

Environmental Impact of Different Materials

Different materials used in facade retention systems have varying environmental impacts. Steel, for instance, has a high embodied carbon footprint due to its energy-intensive production, but its durability and recyclability can mitigate this impact over the long term. Timber, a renewable resource, offers a lower embodied carbon footprint but requires careful sourcing to ensure sustainable forestry practices. Concrete, while durable, has a significant carbon footprint, but can be produced with lower-carbon alternatives like recycled aggregates. A comprehensive life-cycle assessment (LCA) should be conducted to evaluate the environmental impact of each material option, considering factors such as manufacturing, transportation, installation, maintenance, and eventual disposal or recycling. The LCA should also account for the energy performance of the retained facade and its contribution to the overall energy efficiency of the building.

Future Trends in Facade Retention Systems

Source: andrzejzarzycki.com

The field of facade retention systems is constantly evolving, driven by advancements in materials science, engineering techniques, and a growing emphasis on sustainability and building performance. New technologies and design approaches are emerging, promising more efficient, durable, and aesthetically pleasing solutions for building facades. These trends are significantly impacting the design and construction of modern buildings, pushing the boundaries of what’s possible in terms of architectural expression and environmental responsibility.

Several key trends are shaping the future of facade retention systems. These include a move towards lighter, stronger, and more adaptable materials; the integration of smart technologies for improved building performance; and a focus on prefabrication and modular construction to accelerate project timelines and reduce on-site labor. The increasing demand for sustainable building practices is also driving innovation in this area, with a focus on systems that minimize environmental impact and enhance energy efficiency.

Lightweight and High-Strength Materials

The use of high-performance materials like carbon fiber reinforced polymers (CFRP) and advanced composites is gaining traction. These materials offer exceptional strength-to-weight ratios, allowing for the creation of lighter and more slender facade systems. This reduces the overall structural load on the building, leading to cost savings in foundation design and construction. For instance, CFRP can be integrated into existing steel or concrete structures to enhance their load-bearing capacity, making them suitable for facade retention applications. This approach allows for the retention of historical facades while ensuring structural integrity and safety.

Integration of Smart Technologies

Smart facade systems are incorporating sensors, actuators, and control systems to optimize building performance. These systems can monitor environmental conditions, adjust shading devices automatically, and regulate airflow to maintain optimal indoor comfort while minimizing energy consumption. For example, integrated sensors can detect changes in temperature and sunlight intensity, triggering automated adjustments to the facade’s shading elements. This dynamic control enhances energy efficiency and reduces reliance on mechanical climate control systems. Data collected by these systems can also provide valuable insights for building maintenance and optimization.

Prefabrication and Modular Construction

Prefabrication and modular construction techniques are increasingly being adopted for facade retention systems. This approach involves manufacturing components off-site in a controlled factory environment and then assembling them on-site. Prefabrication reduces construction time, minimizes on-site waste, and improves overall quality control. Modular systems are particularly well-suited for large-scale projects, allowing for faster completion and reduced disruption to surrounding areas. The prefabricated modules can be designed and tested rigorously before installation, ensuring accuracy and reducing the risk of errors during the on-site assembly process.

Sustainable and Eco-Friendly Designs

Sustainability is a major driving force behind innovation in facade retention systems. The industry is focusing on the use of recycled materials, renewable energy integration, and designs that promote natural ventilation and daylighting. Examples include facade systems incorporating photovoltaic cells to generate renewable energy or systems designed to optimize natural ventilation to reduce the need for mechanical cooling. The use of recycled materials in the fabrication of facade components also reduces the environmental impact of the building lifecycle. Furthermore, the design of systems that enhance the thermal performance of the building envelope can lead to significant energy savings over the building’s lifespan.

End of Discussion

Source: f-cdn.com

Mastering facade retention systems means understanding not only the technical aspects but also the safety regulations and long-term sustainability considerations. By integrating best practices and staying abreast of emerging trends, architects and engineers can harness the power of facade retention to create innovative, safe, and environmentally responsible buildings. This knowledge empowers informed decision-making, leading to successful projects that stand the test of time.